Extreme weather conditions (extreme heat or cold, and humidity variations) can significantly alter the quality of concrete. In hot weather concreting, one should make sure that all the negative impacts of high ambient temperature are appropriately alleviated by taking the necessary precautions. In this article, we will review how hot weather temperatures can affect the quality of concrete construction. We will also review some of the most important precautions for concreting during the hot season.

What is Hot Weather for Concreting?

Let’s see what hot temperature is for concrete, and why it is critical. American Concrete Institute (ACI) definition of hot weather condition, as stated in the ACI-305R-10, refers to job-site conditions that accelerate the rate of moisture loss or rate of cement hydration of freshly mixed concrete, including:

a) Ambient temperature of 27 °C (80°F) or higher; and

b) Evaporation rate that exceeds 1 kg/m2/h

Canadian Concrete Design code (CSA A23.1/.2) uses the same ambient temperature for hot weather (27 °C).

Challenges of Hot Weather Concreting

How does hot temperature affect concrete? We know that water is a main component in concrete. Increase in the weather temperature increases the rate of vaporization, therefore, hot weather condition increases the water demand in concrete production. Other challenges of hot weather concreting can be summarized as:

1- Accelerated slump loss leading to the addition of water on the job-site,

2- Increased rate of Setting resulting in placing and finishing difficulties,

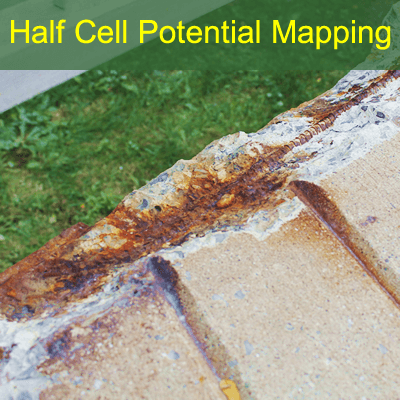

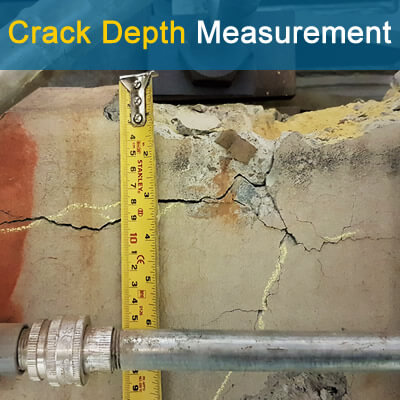

3- Increased tendency for thermal and plastic cracking,

4- Critical need for prompt early curing,

5- Difficulties in controlling entrained air,

6- Increased concrete temperature resulting in long term strength loss.

Precautions for Hot Weather Concreting

Following general precautions will help in performing a successful concreting project in hot weather conditions, and mitigating the negative impacts of hot weather. These precautions would be helpful during concrete production and delivery, and will improve the durability performance of concrete by minimizing undesired cracking.

1- Use materials and mix proportions that have a good record in hot-weather conditions,

2- Cool the concrete or one or more of its ingredients,

3- Use a concrete consistency that allows rapid placement and consolidation,

4- Reduce the time of transport, placing and finishing as much as possible,

5- Schedule concrete placements to limit exposure to atmospheric conditions (i.e. at night or during favorable weather conditions).

General Solutions for Cooling Materials

The usual method of cooling concrete is to lower the temperature of the concrete materials before mixing. The aggregates and mixing water should be kept as cool as feasible as these materials have a greater influence on concrete temperature after mixing than other ingredients. In extreme hot condition, a portion of water can be replaced with ice to lower the temperature. Curing of concrete plays a significant role in reducing the negative impacts of hot weather on the quality of concrete.

Cliffort Vogelland

Working in the Caribbean and South- America forced me to deal with all these environment challenges. Besides of cooling the aggregates and early curing the surface to prevent cracks, using a Concrete Retarder is the best thing to do in the tropic. This delays the hydration heat process of the cement .

Klaas Kinsbergen

Hi Cliffort. we can see clearly that your proposal works. Concrete does not crack and hardens quickly to high values in a few days, without cracking.

Jack Titchener

I really liked how you talked about the need for additional water on the hotter construction sites. I sometimes see the poor construction workers sweating in the heat and have been wondering if there was a faster way to complete the projects they have to do or slow the hardening of the concrete itself. Great job on talking about the concrete, I'll have to consider what you said, while I try to figure out a solution.

Aryan

That's why I usually poor water on our concrete driveways during hot weather. Thanks for these helpful tips. Well done!