The Problem

FPrimeC was retained by Ellisdon to conduct a comprehensive quality control of post-tensioned concrete beams. The beams served as primary load transfer system in a commercial-residential tower in downtown Toronto. Beams were 3 m deep, 2 m wide, and had a free span of approximately 12 m. The post-tensioned beam showed sign of premature cracking as a result of applied load. The initial assumption was that the post-tensioning force were applied early, before concrete achieving enough compressive strength. FPrimeC was called to evaluate the condition of the concrete, and determine if the concrete is of standard quality, or further destructive test is needed. What is post tensioned beam?

Quality Control of Post-Tensioned Concrete Beams

The condition of the beams were monitored using a detailed visual inspection. Existing cracks their size, and orientation were mapped. A test plan involving NDT solutions was designed and proposed to customer.

Non-Destructive Testing

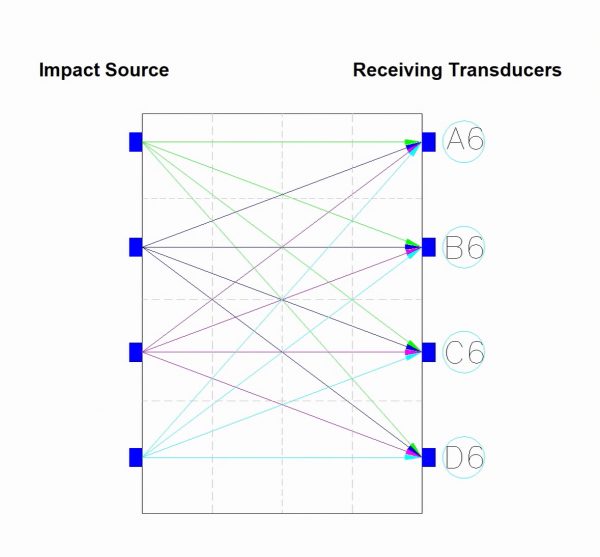

A non-destructive testing solution was designed and involved rebound hammer testing of the concrete beam, as well as ultrasonic pulse velocity measurement. The test helped to perform quality control of post-tensioned beams. The tests were performed in sequential arrangement, and emulated seismic tomography across the cross section. This would allow for deeper and more accurate analysis of wave speed in different parts of the concrete beam. Test results were used in a comparative basis, and enabled client with decision making in the construction process.