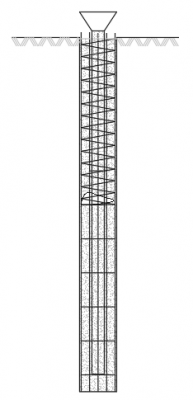

This article describes certain construction practices that can result in integrity problems in concrete piles and drilled shafts. Defects can occur at any point during the construction of bored concrete pile. Most common types of pile integrity issues are presence of voids; inconsistency in concrete mix, concrete; entrapped groundwater or slurry; and geometric errors. These defects can be categorized based on the place in the construction sequence at which the defect occurs.

What is Pile Integrity ?

In general, Pile Integrity refers (ASTM D 5882) to certain characteristics of deep foundations and piles such as:

- Physical Dimensions of Pile (Length or Cross-Section);

- Continuity of Pile (presence of Voids or Major Cracks); and

- Consistency of the Pile Material.

Certain pile construction practices can lead to defects in drilled shafts. These defects can be major voids, poor quality concrete, geometric errors, and entrapped slurry or ground water. These defects may negatively impact the the load bearing capacity and load distribution properties. Piles and deep foundations transmit top structure loads to strong substrate through friction and/or standing on bed rock. This load transmission is performed effectively when there are no major integrity problems in concrete piles; Defects may result in partial settlement to significant damage or collapse of the top structure.

Pile Construction Methods

Before we begin, let us briefly review the main three methods of pile construction:

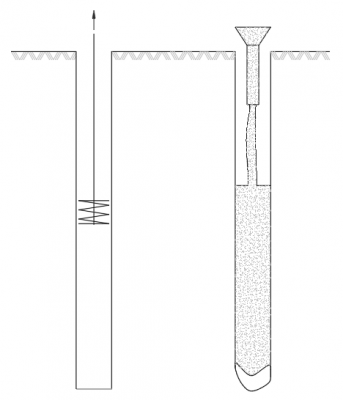

- Dry Method: In this procedure, the borehole is excavated, and backfilled directly with concrete.

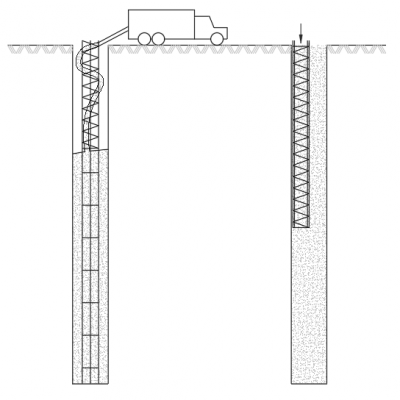

- Casing Method: In this procedure, a temporary casing is used to support the borehole, prevent caving, and prevent intrusion of groundwater before placement of concrete.

- Direct Slurry Displacement: In this method, drilling fluid is used to stabilize the borehole during excavation. The liquid is then displaced by placing concrete under the fluid through tremie pipe.

There are different methods of drilling, and different types of drilling liquid. No matter what procedure is selected by design engineers, it is necessary to make sure no voids, or poor patches form in the concrete pile. One should also make sure that the properties and characteristics of the fresh concrete meets the requirement for the specific drilling method. Guide to Tremie Concrete for Deep Foundations (DFI, 2018) provides the specifications of concrete materials.

Most Common Integrity Problems of Concrete Piles

Construction practices can negatively impact the integrity of drilled shafts. Every construction site is unique, depending on the soil type, and subsurface condition, a suitable construction practice is adapted. This makes the construction of each individual shaft a unique project. Another complication is that both drilling and concerting problems happen within the shaft, far from the curious eyes of contractor or the inspector, making it very difficult to verify the quality, and integrity of drilled shafts (Michael W. O’Neill, TRB, 1991)

The process of quality control for this group of elements is very much through indirect measurement of other parameters, i.e. resistance of pile to driving or drilling, or other non-destructive testing techniques (NDT). NDT methods can shed light on this hidden part of concrete piles. (Learn more: NDT methods of Pile Integrity Testing)

Integrity problems are commonly categorized based on the place in the construction cycle at which the defect occurs:

- Defects arising from general construction problems,

- Defects arising from drilling problems,

- Defects arising from casing management problems,

- Defects arising from slurry management problems, and

- Defects resulting from design deficiencies.

Source: (Michael W. O’Neill, TRB, 1991)

General Construction Problems

Incorrect construction procedures can lead to defects in drilled shafts. Defects arising from general construction problems can be categorized in two general common defects:

- Problems arising from free fall procedure Free fall method for delivering concrete to the bottom of the drilled shaft is permitted if the proper concrete mix is selected. However, without taking the precautionary actions to direct the concrete stream away from reinforcing steel or the sides of the excavation, segregation can happen. This may result in small voids in the vicinity of steel rebar. Segregated concrete is often less dense, and tends to have lower p-wave speed.

- Out of Position Drilling: In general, drilled-shaft contractors should place shafts so that the drilled shaft shall be within 3 inches (75 mm) of plan position at the top of shaft and the center of excavation is vertical to

within 2 percent. When contractor has drilled the shaft out of pre-defined position, it will result in inadequate concrete cover, and eccentric loading of the pile.

Defects Resulting from Drilling Problems

Proper drilling method and equipment should be selected for each job site, otherwise, this may result in certain defects such as sloughing of soil during concreting.

Integrity Problems Resulting from Casing Management

Poor handling and management of temporary casing is a common source of pile integrity problems. Certain issues can arise from improper management of casing:

- Use of Dirty and/or dented Casing: This may increase the concrete-casing shearing stresses (during lifting the casing), which might place tension in concrete underneath the bottom of the casing, and creating “Necking”. This will replace concrete with soil or groundwater, or even voids. In extreme cases, this may result in total discontinuity of the lower section.

- Delay in Extracting Casing: Premature setting of concrete inside the casing, or delay in extracting casing (casing left in borehole) can be a major issue in friction piles, mainly because soil-concrete side resistance is considerably larger than soil-steel resistance.

- Poor Workability of Concrete Mix

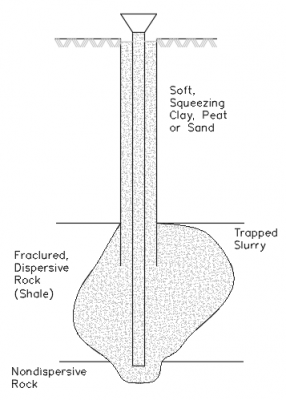

Integrity Problems Arising from Slurry Management

Poor management of slurry can affect the integrity and quality of the concrete piles.

- Improper Cleaning of the Base of the Shaft

- Delay in Placing Steel Cage and Tremie: This issue, along with the one mentioned above can result in creating a bullet shape shaft base (voids underneath); this will impact the base bearing capacity.

Major Defects in Concrete Drilled Shafts

1- Major Voids

Similar to cracks, voids can affect the consistency and quality of pile materials. Voids can affect the load bearing capacity of concrete piles, as they reduce the effective cross-sectional dimension. pile integrity testing does not provide any useful information about the portion of the pile that locates underneath the major voids or cracks.

2- Soil Inclusion

According to HON-FUNG CYRIL CHAN (1987 ) Inclusion of foreign material, soil lumps, slurry, etc. within the body of the pile can negatively impact the integrity of piles and deep foundations. This could happen as a result of borehole wall slide into the hole which can potentially create gaps over length of pile. Soil inclusion can impact the load bearing capacity of the pile. Evaluating soil inclusion through acoustic waves can be quite challenging since the acoustic impedance between the two regions of hardened concrete and soil might not be significant. Methods such as pile integrity test (sonic-echo) can be used to evaluate the integrity issues.

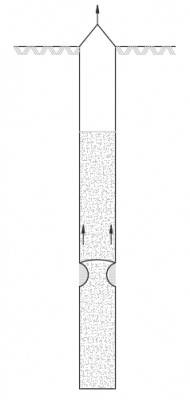

3- Necking

Necking in concrete piles can happen during casting of pile shaft in soft clay. This rapid change of cross section (as a results of necking) can be a source of integrity problem. Necking can affect the load bearing capacity of concrete piles. According to Zhaoyin Zhou, “Poor performance and large water loss of mud causes water swelling of plastic layer or form lax honeycomb thick mud cake; improper distance between neighboring pile constructions, the stresses in the layers of soil has not been diffused, soft clay creeps in new holes, or the bit size wears excessively are the main causes.”

4- Bulging

El-Wakil and Kassim cite that bulging is defined as a kind of pile shape imperfection; bulging increases the pile cross-section in certain areas along the pile length. While bulging may increase the pile ultimate load capacity, it is still considered as a pile defect and should be investigated. Pile integrity testing can effectively help identify bulging and necking in concrete piles.

How To Evaluate Integrity Problems?

According to the ASTM D5882, pile integrity refers to qualitative evaluation of the physical dimensions, continuity of a pile, and consistency of the pile material. Different NDT methods have been developed to assess the integrity of piles and deep foundations:

- Low Strain Impact Integrity Test (Learn More)

- Crosshole Sonic Logging

- High Strain Integrity Test (Dynamic Analyzer)

- Thermal Integrity Profiling

How to Perform Pile Integrity Test | FPrimeC Solutions

[…] structural elements (ASTM D5882). Sonic Echo (SE) and Impulse Response (IR) are employed for the integrity test on deep foundation and piles. The test results can be used for evaluation of the pile […]

Reuse of Existing Piles - How NDT Can Help | FPrimeC Solutions

[…] and integrity of existing piles. NDT methods are extensively used for evaluating pile length and integrity testing. However, there is no unique NDT solution that covers answers all questions. A combination […]

ahsan

yes, PIT is becomming popular.But without having site representative pile(a referrence pile) the interpretation of PIT originating graphs may mislead to conclude on problems.

How to Perform Pile Integrity Test – iPile

[…] structural elements (ASTM D5882). Sonic Echo (SE) and Impulse Response (IR) are employed for the integrity test on deep foundation and piles. The test results can be used for evaluation of the pile […]

Reuse of Existing Piles - How NDT Can Help - iPile

[…] and integrity of existing piles. NDT methods are extensively used for evaluating pile length and integrity testing. However, there is no unique NDT solution that covers answers all questions. A combination […]

Jack Titchener

I never knew that there could be bulging in concrete piles. I guess I could see this happening if there was swelling in the soil. I'll have to remember your tips if I ever work with piling.

Mudassar Sattar

But still there is challenge of diameter to depth ratio which is 1:30. So deeper pile depth quality verification is still a challenge.

Quality Control of Concrete Piles | FPrimeC Solutions

[…] following article describes some of the most common integrity issues in pile construction and […]

wak

can i request method statement how to rectify secant pile wall necking with the suitable material

What is Pile Integrity Test ? | FPrimeC Solutions

[…] structural elements (ASTM D5882). Sonic Echo (SE) and Impulse Response (IR) are employed for the integrity test on deep foundation and piles. The test results can be used for evaluation of the pile […]

Daphne Gilpin

Thanks for explaining that quality control for concrete piling has to be done through measures of indirect parameters, so it should be done by someone with experience. I'm trying to learn more about concrete piling so I can evaluate our options for the foundation of our custom home. I'm glad I read your article because now I can see why it's important to find the best contractor for the job.

Takia

What type of soil causes over cutting of holes??? Please leave me an answer. Thank you

vrc

how could we ensure that there is no voids in pile during concrete pouring.

Tamer

What is the expected percentage of failure of these piles?

I mean ... if you pour 10 piles

How many piles succeed and how many fail?

תבניות קלות לבנין

After checking out the various problems that could have arrived with concrete piles, it can be said that integrity is not really doing well with the designed structures. I might say that using easy-to-building molds can help us out solving this issues.

Chance Cook

I had no idea that piling could lead to defects in drilled shafts if not practiced properly. That just sounds like a disaster waiting to happen. So I'd rather plan for something safer from the beginning.

Marcos Moises Moreno

is cement lumps considered one factor of Pile Integrity Test failure? Or defective pile