Harvesting wind energy has been of special interest over the past decade. There are approximately 300 wind farms across Canada.Wind turbine structures are very complex. While the inspection of the turbine and tower has been very well developed, the literature on evaluating the quality, integrity and reliability of their foundation is relatively limited.In this article, we will review how Non-Destructive Testing of Wind Turbine Foundation can help engineers in the process of Quality Control and Quality Assurance.

Over the past decade, Canada has heavily invested in wind energy, increasing its annual capacity from nearly 2,000 MW in 2008, to 13,000 MW in 2019. That is enough to power approximately 3.3 million homes – 6% of our country’s electricity demand (Canadian Wind Energy Association, 2019).

There are 299 wind farms operating from coast to coast, including projects in two of the three northern territories.

While the quality control, routine inspection, and performance monitoring of the turbine and the blades have significantly developed over the past few years, the quality control and monitoring of the foundation elements is often overlooked (Carles Nmai). This is essential in keeping these massive towers grounded and secure.

Wind Turbine Foundation

Wind Turbines are often supported on massive concrete foundations:

- Wind Turbine foundation can be as large as 10-15 meters (diameter),

- The Foundation block can be as thick as 1 to 2 meters, depending on the tower size, and soil characteristics.

Due to their relatively large size, these foundations are often considered mass concrete (What is Mass Concrete?).

This can lead into buildup of significant heat (from the cement hydration process) and develop massive temperature gradient in the foundation block. This may result in thermal contraction cracking shortly after the concrete hardens — compromising the structural integrity and durability of the foundation.

Adapted from Henvey Inlet Wind Project Website, Sep 2019

Wind Turbine Foundations have sophisticated congested steel reinforcement to provide stability against dynamic loads. This will make the placement of concrete challenging, and it may result in poor quality patches in the foundation.

While the use of Self-Consolidating Concrete (SCC) and steel fibres can help overcome some of these challenges, by reducing the amount of steel bars, and proper placement. However, the quality of foundations needs to be evaluated ahead of installing the tower and the turbine.

Quality Control of Wind Turbine Foundation

Routine quality control tests such as slump test (flow test in case of SCC), air content, and strength measurement are necessary to monitor the strength development in concrete mass foundations. The process of concrete placement and curing should be carefully planned.

Any interruptions in work, or change in work order should be fully recorded. After placement, proper curing regime should be adopted to eliminate the risk of early age shrinkage cracking.

Another issue could be alkali-silica reactions. Since these foundations are normally exposed, the risk of ASR will be high should the aggregates are potentially reactive.

Non-Destructive Testing can be used to evaluate the quality of these foundations during and after hardening.

1- Temperature and Strength Monitoring

Monitoring temperature gradient in mass concrete is important in minimizing the risk of cracking after hardening. Temperature sensors (wired and wireless) can be used to collect information from different locations of the foundations. Moreover, depending on the type of concrete, this information can be translated into concrete strength using maturity method.

Maturity method provides a simple approach for evaluating the strength of cement-based materials in real-time, i.e. during construction .

2- Ultrasonic Tomography

Ultrasonic Tomography can be used to evaluate the shallow depth deficiencies in the foundations. Depending on reinforcement pattern, this technique provides a reliable and cost-effective tool to scan concrete for potential defects. The method works based on transmitting and receiving ultrasonic signal from an array of transducers; the collected signals are merged to develop 2D maps of sub-surface defects, or other anomalies.

Copyright reserved for KIWA GmbH (Dr.-Ing. Andrei Walther) – Used by Permission

3- Impact-Echo

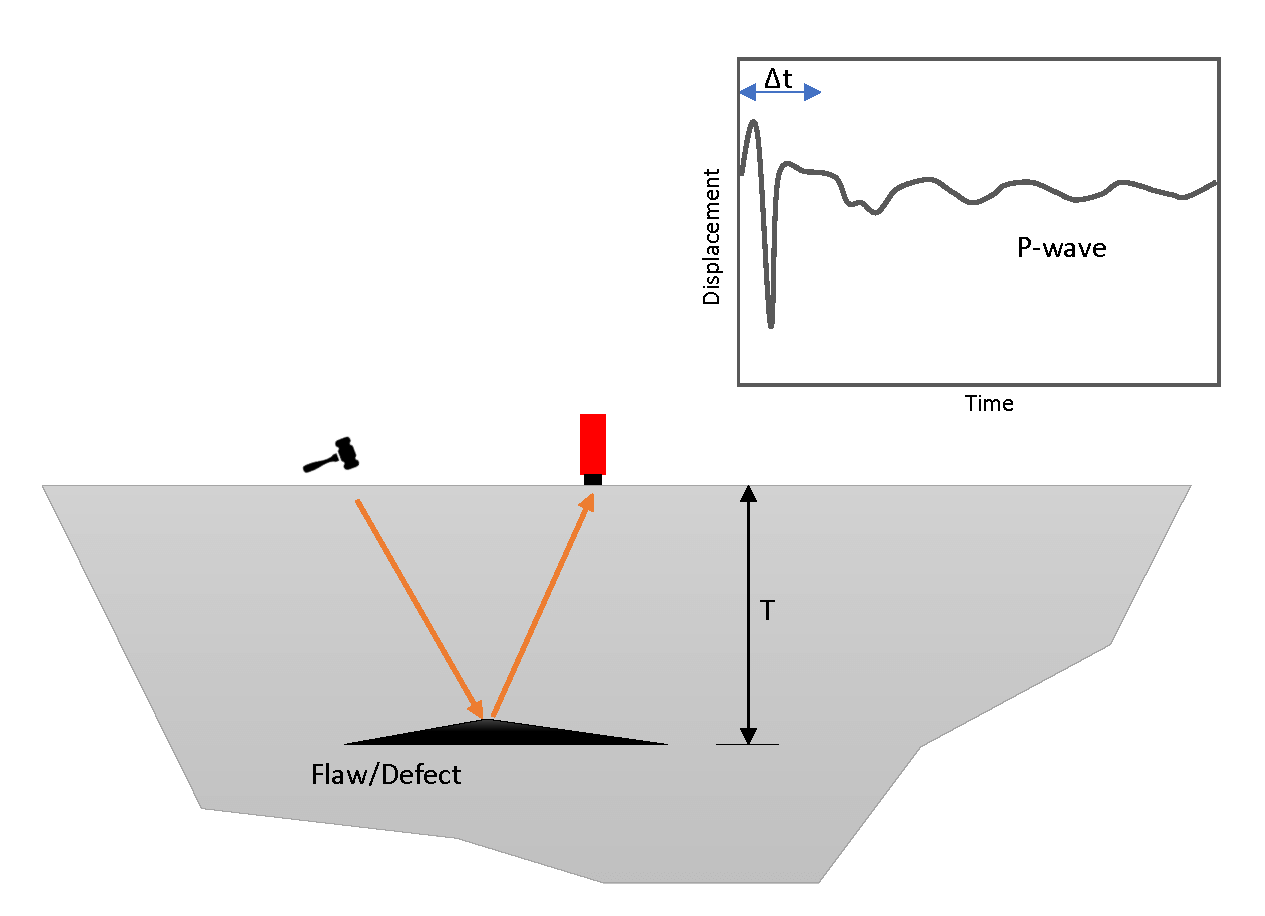

Impact-Echo is a nondestructive test method for evaluating concrete and masonry structures. The test utilizes stress waves (sound) that is normally generated through striking concrete by an impactor (Impact), and recording the reflections and refraction from internal flaws and other boundaries (Echo).

As P- and S- waves propagate within concrete element, they get reflected by internal interfaces (concrete-crack, concrete-air, concrete-rebar) or external boundaries. The arrival of these echos on the surface induces displacement. This displacement can be measured by placing a sensitive transducer (which then converts displacement or acceleration into electrical voltage). Data is recorded by a data acquisition and data logging system. Learn More about Impact-Echo

The method can be used to identify delamination, discontinuity and major voids within the foundation blocks. In foundations with known thickness, the results can be analyzed to show the depth of defects.

4- Ground Penetrating Radar

Ground penetrating radar (GPR) is a very useful technique for nondestructive concrete imaging and scanning. GPR uses pulsed electromagnetic radiation to scan concrete. GPR consists of a transmitter antenna and a receiver antenna, and a signal processing unit. GPR emits electromagnetic pulses (radar pulses) with specific central frequency to scan the subsurface medium. The reflected waves from subsurface layers, and objects are captured by the receiver antenna.

Cracks in Wind Turbine Foundation

It is critical to repair early age cracks in wind turbine foundations. Wind turbine structures are subject to dynamic loads from the oscillation of tower, blades, and the operation of turbine. Due to this changing load, the cracks can progress in width, and depth, creating durability related issues and structural performance concerns. epoxy injecting into these cracks can help control these cracks at the early stage.

Non-destructive Testing of Concrete Foundations | FPrimeC Solutions

[…] A combination of these techniques help engineers collect critical information about structural details (as in the case of detecting rebar spacing in an existing foundation), as well as internal anomalies, such as void or discontinuities. Learn More […]