On-site Evaluation of Concrete Strength is a main challenge in the condition assessment of existing infrastructure, or the quality control of new construction. Owners, maintenance managers of such existing concrete structures normally prefer non-destructive and non-intrusive methods to avoid further damage to an already struggling structure. In construction projects, switching to non-destructive means less intervention, shorter down-times, and saving money. However, all parties agree that the strength of concrete is a critical parameter. In this article, we will review the potential options and practical solutions for on-site evaluation of concrete strength.

On-site Evaluation of Concrete Strength

Concrete strength (compressive strength) is by far the most important property of concrete. It represents the mechanical characteristics of concrete; The 28 days compressive strength of concrete cylinders or cube samples has widely been accepted as the minimum specified concrete strength in most design codes (ACI 318-14, CSA A23.3-14). Concrete Strength is also considered a key factor in obtaining desired Durability Performance.

Evaluation of Concrete Strength is an important task:

- Existing Structures: Concrete Strength is of special interest for engineers involved in the Structural Condition Assessment of concrete structures. It is used to assess the mechanical characteristics and durability performance of concrete.

- New Construction: Concrete Strength is usually monitored during the construction process. Construction engineers, project managers, and Quality Control and Quality Assurance auditors depend on the compressive strength test results. When compression test on concrete cylinders yield low breaks, engineers require reliable tools to assess the actual strength of concrete.

Nondestructive testing (NDT) offer an interesting approach to evaluating the compressive strength of concrete. NDT methods provide access to material properties while remaining rapid and of moderate cost (Breysse, 2012). The following article will take a quick look at some of the major non-destructive testing solutions for on-site evaluation of concrete strength. In the first part, we will present and discuss NDT methods for evaluating concrete strength in existing structures. In the second part, we will present and review the NDT methods for evaluation of early age strength of concrete.

Part I – Existing Structures

1- Compression Test On Concrete Cores

Extracting concrete samples (Read More: Challenges of Concrete Coring) and testing for compressive strength is often considered the most cost-effective and most reliable solution. In fact, many codes and guidelines consider this the only approved method for evaluating concrete strength. In this case, concrete core is taken from the existing structure.

The core needs cutting (sawing) and surface preparation. The core is then tested for compressive strength. However, the reality is far from this. There are certain questions that needs to be answered: Where to take concrete cores from? How to handle cores properly (maintain moisture, safe mobilization)? How many cores will yield reliable information?

Pros

- This is the most reliable method to estimate the compressive strength. The method is relatively fast.

Cons

- It is destructive. Not only it damages concrete integrity, it might affect reinforcing bars in RC structures. Rebar locating tools, such as Ground Penetrating Radar – GPR are needed to avoid this problem.

- Selecting test locations can be difficult. Selecting the best location of cores is relatively subjective.

- The locations of cores needs to be repaired.

- Coring is not an option for owners of important structures, especially when there are concerns about further damaging the structure.

Read More: Challenges of Concrete Coring

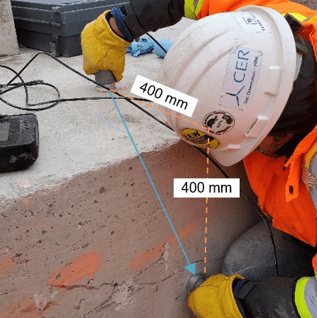

2- The Pull-Out Test

The concept behind Pull-Out Test is that the tensile force required to pull a metal disk, together with a layer of concrete, from the surface to which it is attached, is related to the compressive strength of the concrete.The pull out test is normally used for early diagnosis of strength problems. However, it can be used to evaluate the strength of concrete in existing structures. Pull out testing involves attaching a small piece of equipment to the exterior bolt, nut, screw or fixing. This is then pulled to the designated stress load level to determine how strong and secure the fixing is.

Pros

- Relatively easy to use

- If relationship to strength is established, the method can deliver robust test results.

Cons

- Pull-Out test often involves crushing and damaging concrete

3- Rebound Hammer For Concrete Strength

The Rebound Number of Hardened Concrete (see ASTM C805) can be used to assess:

- In-place uniformity of concrete,

- to delineate variations in concrete quality throughout a structure, and

- to estimate in-place strength if a correlation is developed (Read More)

The Rebound Hammer works based on the rebound principle, and consist of measuring the rebound of a spring driven hammer mass after its impact with concrete. New versions of the test have been commercialized and are used to help engineers and inspector with a wider range of material properties.

Due to its simplicity and low cost the rebound hammer is the

most widely used nondestructive test for concrete. It is frequently used-although by mistake- as a tool to assess the strength of concrete. Malhotra (2004) argues that “there is little apparent theoretical relationship between the strength of concrete and the rebound number of the hammer. However, within limits, empirical correlations have been established between strength properties and the rebound number. ACI 228.1R describes a standard procedure to calibrate test results for every specific project, and use project-specific correlation to assess the strength. This will minimize the number of intrusive tests.

Pros

- It is easy to use for most field applications.

- The test can be used to study the uniformity of concrete

Cons

- surface condition, presence of rebar, presence of sub-surface voids can affect the test results

Read More: Estimate Concrete Strength Using Schmidt Hammer

4- Ultrasonic Pulse Velocity

Ultrasonic Pulse Velocity (UPV) is an effective method for quality control of concrete materials, and detecting damages in structural components.

The UPV methods have been traditionally used for the quality control of materials, mostly homogeneous materials such as metals and welded connections. With the recent advancement in transducer technology, the test has been widely accepted in testing concrete materials. The test procedure has been standardized as “Standard Test Method for Pulse Velocity through Concrete” (ASTM C 597, 2016).

The concept behind the technology is measuring the travel time of acoustic waves in a medium, and correlating them to the elastic properties and density of the material. Travel time of ultrasonic waves reflects internal condition of test area. Some researchers have tried to develop a relationship between the strength and wave speed.

Pros

- UPV can be used to detect other sub-surface deficiencies

Cons

- The method is affected by presence of rebar, voids, and cracks.

- There is no enough results for assessing the reliability of the method in the field.

5- Combined NDT Methods

As we discussed above, Rebound Hammer and Ultrasonic Pulse Velocity are the most widely used NDT methods for evaluating concrete strength in existing structures (Malhotra, 2004)

Combined methods involves a combination of NDT methods for predicting the on-site strength of concrete. The combination of UPV and Rebound hammer has been studied by several researcher. Breysse, 2012 have conducted a comprehensive literature review on the combined methods.

The improvement of the accuracy of the strength prediction according is achieved by the use of correction factors taking into account the influence of cement type, cement content, petrologic aggregate type, fine aggregate fraction, and aggregate maximum size. The accuracy of the combination of rebound hammer and ultrasonic pulse velocity results in improved accuracy in estimating the compressive strength of concrete (Hannachi and Guetteche, 2012).

It is very important to consider that the accuracy of each and every relationship depends on the calibration and correlation that is made with destructive tests (core samples). While combined methods still rely on intrusive tests to yield accurate outcome, they have a huge potential to reduce the number of destructive tests on a job site.

Part 2 – New Construction

1- The Maturity Method

The maturity method is a technique to account for the combined effects of time and temperature on the strength development of concrete.” (Carino and Lew, 2001). Maturity method provides a simple approach for evaluating the strength of cement-based materials in real-time, i.e. during construction. The test procedure has been standardized in the ASTM C1074 – 19

Maturity method uses the history of temperature variation in concrete elements. Termocouples (wired or wireless) are embedded within concrete, and the temperature variation of concrete during the curing process is monitored in real time.

The Maturity Index is used to correlate test results from Maturity test to compressive strength obtained from cylinder samples cured in laboratory condition. The relationship can be used to monitor strength development in fresh and early age concrete.

Francesc servos Ros

Dear Mr.

For a long time, I have been studying the easiest and most reliable way to control the strength of the concrete and come to the following conclusions:

-The test pieces will be cubic 10x10x10cm, very manageable, light weight, take up little space, do not have to modify and little final residue.

-The machine for the breaks, may be less capacity, but cheaper.

-Use heat curing with wet temperature and you can create a curve of resistances in the time obtaining a very sure estimate of the resistances at each age.

Regards

Gordon Chirgwin

The UPV is not suitable on its own. It is more closely related to the stiffness and density of the concrete than it is to strength (Chirgwin, Thesis for Masters of Engineering Science, University of Sydney, 1988). It is also affected by the saturation of the concrete. Also, the correlation to strength has such wide error bands that it is difficult to tell a 50 MPa concrete from a 30 MPa concrete.

The other, unmentioned issue with coring is the restriction on coring sites. Congested areas may be the most problematic for the concrete quality, but the most problematic for strength.

You have omitted a critical method for estimating the concrete strength gain in-situ during construction: The Maturity Method. Preferably, a series of strength curves are set up ahead of time to check the strength gain under standard, accelerated and retarded conditions over 28 or 91 days. The maturity of the concrete is then assessed using a maturity meter (See J. J. Carino "CN Tower" circa 1976). Samples should be taken, cured and tested at suitable intervals (1, 3 and 7 days) to check that the concrete is the approved mix.

FPrimeC

Gordon,

Excellent points. The main purpose of this article was to review available techniques. Most NDT methods have certain limits in field application. We believe an appropriate combination of NDT can reduce the number of destructive test. We have a separate article for maturity method. https://fprimec.com/non-destructive-evaluation-of-unknown-foundations

Ed

The windsor probe worked well for Florida Aggregates--Very accurate

When we as a Ready Mix Producer had suspect strengths, we used the tested the concrete with a windsor probe. If the windsor probe told us the concrete met design strength it met design strength.

Yngve Alvarsson

The fact is that all 5 methods are not any good to evaluate the Concrete Strength. Now one is good enough !

In year 2017 soon coming is it a shame that we do not have better methods in construction.

We need to try harder in the coming years. (Did not 3 men go to the moon already in 1969?)

Let´s hope everyone working in the concrete business will start to "think outside the box" and that we try to improve many type of tests that we today use. The Average Strength, now known in the middle of a structure, is only one parameter. Surface or the upper one inch concrete quality is also important, some times more important. How do we measure that in a simple way in a bridge deck or in an other wearing surface? Any idea?

Happy new year! Yngve

Yngve

RolliT

Oliver Aguirre

Dear Yngve,

Many engineers in Europe and USA are useing the pull-out method to assess strength of existing structures (slabs, piers, beams, columns) succesfully. It is recomended to use the method by making correlations to cores of the same structure (as this publication specifies). However, there is documentation on how the method is very reliable even when using the manufacturer given correlation, wich was done by testing data of all sorts of concrtes and different laboratories. In my mind, pull-out is very well correlated to cylinder/cores because the failure mecanism is very similar.

Sergey Drabkin

Designing concrete structures requires substituting f'c in empirical formulae. There is only one way to get this value - compressive test on samples. All other methods may only be correlated with compressive test but their results cannot be substituted in the formulae. It is a matter of engineering judgement if f'c from NDT correlations may be used to verify design assumptions. The best design may fail. In that case, if the Engineer of Record (EOR) has used method prescribed by Codes to assess f'c, then the EOR will not pay. The engineering judgement will be questioned by the court, and EOR may pay. Hence, any NDT, both existing and developed in the future, have very limited value in formal cases. We can use them in many cases to get general feeling of the situation, but not more than that. Publication in a good journal may be considered by a court, but a good attorney may always question its validity. And EOR may pay. To risk paying a judgement or not to risk is personal choice of the EOR. So in the world of real construction NDT is useful in very limited cases and never for formal assessment f'c. In academic world, NDT is very useful for getting points for publications. But this is a very diffirent story.

Jay Jorgenson

It seems really important to me that you would want a site evaluation, especially when it comes to the strength of your concrete. A couple of years ago, I was walking on the sidewalk of privately owned property and it ended up caving in once I stepped on it! That is definitely a no-go and I can imagine how you would want to prevent that with a good evaluation first!

Ultrasonic Testing of Concrete | FPrimeC Solutions

[…] 5- Prediction of Compressive Strength of Concrete (read more) […]

Ultrasonic Testing of Concrete | FPrimeC Solutions

[…] 1- Pulse Velocity Determination 2- Concrete Quality Assessment 3- Establishing Homogenity and Uniformity of Concrete 4- Measurement of Surface Crack Depth 5- Prediction of Compressive Strength of Concrete (read more) […]

Theodoros Sainis

Dear All,

Should be there a correlation and calibration of the rebound hammer device with each specific type of concrete mix for the evaluation of strength ? Is there any specific method for this type of calibration linking rebound hammer device and a concrete mix design ?

Thank you in advance.

4 Methods of Condition Survey for Bridge Decks | FPrimeC Solutions

[…] Condition Survey using Ultrasonic Pulse Velocity can be use to evaluate the quality of concrete quality (learn more), evaluate Homogeneity and Uniformity of Concrete, Measurement of Surface Crack Depth (read more), and prediction of Compressive Strength of Concrete (read more). […]

What NOT TO EXPECT from Pile Integrity Testing | iPile

[…] to evaluate the strength of pile. PIT uses predicted wave velocity to evaluate the pile length. LEARN MORE about NDT methods that can be used for evaluating concrete […]

Precautions for Cold Weather Concreting | FPrimeC Solutions

[…] Read More: On-Site Evaluation of Concrete Strength […]

Bree Ward

I like your suggestion about concrete strength evaluation. It's a good thing that you mentioned ways on how to do it, especially that the strength is considered as a key factor for durability performance. If I were to work in a building construction project, I'll hire a reputable concrete delivery service that can make our work easier. There will be no need for us to do the mixing process and other stuff. I will also do your suggested concrete evaluation methods. Thanks!

What is Ground Penetrating Radar | FPrimeC Solutions

[…] growing in condition assessment of civil structures. NDT methods are commonly used to evaluate the strength of materials (e.g. strength of concrete, consolidation of soil), to detect/localize embedded objects (e.g. pipe […]

Estimate Concrete Strength Using Rebound Hammer | FPrimeC Solutions

[…] Click here if you would like to learn about other non-destructive methods for on-site evaluation of concrete. […]

Sani

Hi,

Some of our structures compressive strength result was failed. When we do the hammer test its also fail, then we went for ultra sonic test .Based on ultra sonic test most of the structures is passed.

Can we trust the ultra sonic test?

If some one have experience please guide.

Shashikant Valiani

It is difficult to understand that concrete passed based on UPV when failed in all other tests. - Shashi

Arjun singh

Thank you so much for ultrasonic pulse velocity test, I was searching for it.

hardik

this all are after the construcion work done.so is there any method by which we can determine the strength of concrete in 30 minutes or one hour.

Proceq

I think your 'cons' concerning the Rebound Hammer may be a bit overstated. Using the rebound hammer over a large area ensures that there is a lager data set to sample

Elias Delash

is this applicable for old concrete dam?

Kumavat Hemraj Ramdas

In case of rebound hammer strength, it is essential to calibration and reliabikt of results considered for exact relationship between rebound number snd compression strength. Otherwise more variability obtained in results due to influence factor ( cement type, compaction and curing methods, temperature variations, water to cement ratio)

Alex Lyon & Son

This blog happens to be one of the best blog on on-site evaluation of concrete strength, and both limitations and delimitations of it. It is just a proper critique blog, would suggest to others as well. This is a great addition tips blog, thank you for sharing this article.

rachel frampton

I've been planning to hire a service that will be able to run an array ultrasonic examination on the apartment building that is currently being constructed. I agree with you that concrete strength revelation is beneficial in terms of assessing mechanical characteristics. It's also interesting to learn that the rebound number of hardened concrete could also help estimate the concrete's strength.

Matt

Interesting read, especially the Ultrasonic Pulse Velocity section. A lot to learn here, thank you for the great content!

Flat work

Compression Test is the first priority for a new concrete project, And you shared most things out is related to future work. Thanks

Franklin White

Thanks for explaining that the best way to test your concrete's compressive strength is with a compression test. I want to make sure the concrete I get is strong. I'll have someone lay it and then do a compression test afterwards.

Testing the Durability of Your Concrete | Heartland Industries

[…] you’ve gathered the answers to these questions, you will need to test your concrete’s strength. Thankfully, this is a relatively easy and consistent task that can be done despite any […]

James Brewer

Great info. We have been in the business for a while and Just randomly came across your site while learning about using the Ultrasonic Pulse Velocity method. I am still learning...so I appreciate the knowledge so much. All the best in future business!

gggclaboratories

It is a great blog post.I am always read your blog helpful and informative tips. I like it thanks for sharing this information with us

Chris Pederson

I had no idea that they cut the concrete core to determine its strength. I figured they would drop or pour things on it. Well, I guess cutting it would also give them a good idea for its strength and how well it holds up to a saw.

Taylor Hicken

You made a good point when you shared that extracting concrete samples and testing is the most effective solution to test its compressive strength. It is wise to cut or saw some of it by using the proper tools and equipment that can do the job efficiently. I would like to think if a company is planning to test the strength of its concrete, it should consider hiring a reliable service that can offer to do so.

Kristofer Van Wagner

Thank you for highlighting that construction concrete is best done by professionals as they are equipped with the necessary tools, equipment and skills. My wife and I are planning to have our dream house built. I will definitely make a point to hire a professional team.

Scott Dyer

Interesting! In the future, I would contribute and add fracture mechanical methods, which are superior to simple tensile strength tests.

Robert T. Ball

I read your article 5 Methods for On-Site Evaluation of Concrete Strength and its inconceivably consistent for me. By then they clear your pack and stay away for the unsure future it.

토토

nice . thanks for sharing .. .. .

waterproofing Bay of Plenty

Thank you for bringing such topic into light, I really loved the concept of your article. Thanks for sharing this information. It’s a great source of knowledge; I think it will be helpful for lot of people who are looking for learning more about on site evaluation of concrete strength.

Eli Richardson

It's great that you talked about the importance of evaluating the strength of your concrete project. Recently, my wife and I started to make some repairs around the house, and we noticed there's something wrong with our concrete entrance. We'll be sure to follow your advice and look for a professional contractor. Thanks for the information on concrete structures.

Stephen Mocko

It is really important to learn about on-site evaluation of concrete strength. Because concrete strength is affected by many factors, such as quality of raw materials, water/cement ratio, coarse/fine aggregate ratio, age of concrete, compaction of concrete, temperature, relative humidity and curing of concrete. And you have done excellent works here..

Steve

It’s a great source of knowledge; I think it will be helpful for lot of people who are looking for learning more about the concrete strength. Thank you very much for sharing this article.

brick masonry construction

Kristofer Van Wagner

I like that this post shared that when looking for a developer, it is important for us to consider their experience. My wife mentioned she needs a bridge built. I will keep this information in mind.

Prasad

I read post, 5 Methods for On-Site Evaluation of Concrete Strength. Thank you for sharing this informative post.

Suzanne_SM

I think this is a great article. I mean it is well written and detailed. Thanks for using a lot of information that the reader can understand, more in the way that an article can be understood by the reader rather than just confusing them with a bunch of technical languages that they don't understand like what most online writing does! Thanks for sharing this article, it was a very educating experience!

contractors2021

It is a very interesting article. You have interesting facts to share. Thank you for sharing. There is a great deal of information available on this topic at Concrete Contractor Lincoln NE, so visit their website for more details, www.lincolnneconcreteservice.com.

Chris Pederson

It's good to know that a relationship to strength method can deliver robust test results. I had no idea these tests could be done. But having them seems important.

Braden Bills

I want to get a concrete path installed. It makes sense that I would want to get a professional to mix it for me. That seems like a good way to ensure that paths are put in properly.

Greg

I think this is a really cool topic you are exploring-- the best way for engineers to be able to assess concrete strength in order to fix cracks before they get worse. Really well written and informative!

Thanks for posting such an awesome article!

roofing vancouver bc

Tex Hooper

Great tip about having aggregate traction for concrete builds. I need my foundation inspected by a professional. I'll have to make sure any cracks are filled in.

Ismael

I just read your article on Concrete Strength Evaluation. It's a really good article and I learned a lot from it! Thanks for taking the time to write it and share your knowledge with the world. roofing nanaimo bc

Steven

Awesome information here extremely useful! Thank you for taking the time to write this. cement pads Calgary

Adam Golightly

I can see how a business could really benefit from getting the right kind of concrete strength while they are building. Getting some help from a professional could allow them to be safer. It was interesting to learn about how concrete in existing structures can be tested by pulling a metal disc to determine how strong the fixing is.

Mia Evans

Thanks for pointing out that nondestructive testing would be a good approach to evaluate the strength of concrete. I will keep that in mind now that I might need this kind of service for my property to ensure that everything will be durable. It's because I need a concrete water tank installed to have a place to store water for emergency purposes.

Suzanne Mangrum

Hey FPrimeC,

I really enjoy reading your blog! I was so excited to find a post about concrete strength. It's such an important topic and an invaluable resource for everyone in the construction industry and also in the masonry service. The article had some pretty cool info on how to measure it clearly summarized with 5 methods. What a great read!

Greg Sureseal

These five methods for on-site evaluation of concrete strength are fantastic, and I am glad these methods are shared here. I hope that I can utilize these methods when I am working on substantial projects.

Contractorfinder

I am working on this position in my company, so I understand your tips and thoughts! I agree Using correction variables, which take into consideration cement type, cement content, petrologic aggregate type, fine aggregate percentage, and aggregate maximum size, the accuracy of the strength forecast has been improved.

Millie Hue

I totally agree when you said that we should ensure that the accuracy of each step would be depending on the calibration and correlation of the construction process. I guess it is best to hire professionals for bored piers construction to ensure that the proper procedures are followed. It will give the property owner peace of mind that the structure will be durable and will not even have legal issues with regard to the regulations of the state they are in.

Peak Masonry

I just saw and loved your article and wanted to say thanks for posting it. I really appreciated the 5 Methods for On-Site Evaluation of Concrete Strength you talked about. This is a topic that has been on my mind quite a bit lately as well.

You're awesome!

-Peak Masonry

Hardy Flatley

Nice Article...Very interesting to read this article. I have learned some new information. Thanks for sharing.

sanjay

Thank you for writing the article about the on site evaluation of the Precast concrete strength.

alister

amazing article thanks for sharing with us

Mike

I came across your blog post on concrete strength and found it very informative. I am looking for a way to measure the compressive strength of concrete without breaking it apart. What tool would you recommend?

-residential roofing contractor

FPrimeC

Please use any of these methods (rebound hammer) to get an idea. Getting actual results might be difficult depending on the job site and condition.

Weareseos

I’m so thankful for your helpful post!

The yard group

Nice Blogs!

Thanks for sharing this informative blog.

Ordering with The Yard is easy, just call in and give the customer service representative the information needed below. You will be talking to an experienced concrete allocator who will confirm the specifics of your order and the delivery times.

Barry E. Holland

I really appreciate that you shared this amazing post with us, thanks for sharing and keep up the amazing work.

Richard Ayala

In fact, many codes and guidelines consider this the only approved method for evaluating concrete strength. I’m so thankful for your helpful post!

Jeff Carbine

I never knew that concrete strength is usually monitored during the construction process. I never thought that it would be like this, it is really a good article. Thank you for the information about break wall repairs Windsor.

PCTE

Great blog! Everyone should know the importance for concrete testing. Keep it up!

Hardy Flatley

This blog is very nice blog and I got more information from this blog. This blog is very great for information.

haneefa

UPVS testing techniques or rebound hammer test wouldn't give the exact results of what we expected criteria unless otherwise rebar should not cross over the testing area . as important factors to be consider to know the rebar location and direction to have a valuable result after putting our efforts practically and economically

Andrew

Thanks for putting this article together! When do you find measuring the concrete strength most useful?

Greg

Cool article you posted! I know how difficult it is to find accurate information on the topic of concrete strength.

I've found many masonry repair bc contractors are using our website's blog post on this subject as well. It's a great way for them to get up-to-date information from industry experts and also share with their customers too.

Sander

Thanks for the article you posted on concrete strength. I found it really informative!

-https://www.masonrybc.ca/

benny

Thanks For sharing Useful Information

Ryan Smith

Thank you for this informative blog! Just to add up, Concrete suppliers and contractors need accurate, on-site testing of concrete or mortar strength so they can make the adjustments necessary to satisfy their customers and build high-quality structures. But transporting a full-sized laboratory to a job site is not always practical or convenient. This publication describes the most common methods for field evaluation of concrete strength. If you want to know more about visit our site Concrete Contractor Nashville TN.

.

Fred

I read your post on concrete strength and wanted to reach out. I'm a civil engineer and have been in the business for over 10 years. I found your article really informative and it was great to see someone else talking about this important issue. I'm currently working on a project that requires me to evaluate the concrete strength of existing structures.

PCTE

Helpful and fine content about concrete compression test. Thanks for the information!