Corrosion of steel reinforcement is often investigated in the context of the durability performance of the structure; however, corrosion can equally impact the structural performance. Steel corrosion may result in reduced flexural capacity (loss of rebar cross section), reduced bond, and limited ductility. In this article, we will review some of the most important effects of steel corrosion on structural performance of reinforced concrete elements.

What is Steel Corrosion?

Corrosion is a chemical process, in which refined metals such as steel revert back to their lower energy, more natural and stable state of ore (i.e. iron oxides). The phenomena is scientifically explained with the Law of Entropy. The reaction happens with losing steel material and producing red rust, which is generally 4 to 7 times larger in volume. The increase in steel volume increases stresses in concrete to an extent that it can crack, resulting in delamination in concrete bridge decks or parking garage slabs, and loss of concrete cover in beams, girders, and columns.

Structural Effects of Corrosion

1. Loss of Strength

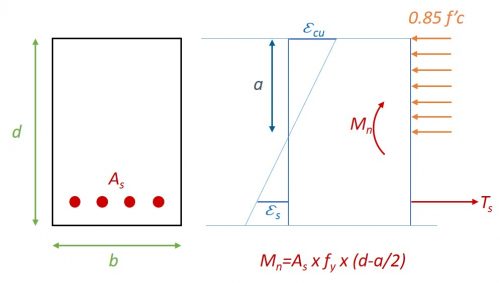

Steel corrosion reduces the effective cross section of structural components. This reduced cross section will reduce the capacity of concrete elements, such as slabs, columns, and beams. Loss of section strength can be crucial in bridge decks, and parking garages slabs.

A major concern is that corrosion of steel components (bars, beams, strands) does not always have visual sign, which makes the inspection process very difficult. The collapse of Algo Centre Mall is a great example of losing capacity and integrity in structural elements that remained unnoticed during the visual inspections. The corrosion of steel elements covered by insulations and fireproofing materials is a major concern in many refineries, industrial plants, and pipelines.

Steel elements covered under fireproofing insulation experience corrosion over their service life. Another famous example is the reduced flexural, and shear capacity of the RC element. Du et al (2005) developed a mathematical model for the residual area and strength parameters (such as yield strength). This formula described the residual area based on the corrosion rate of steel bars.

Corrosion can reduce the effective cross sectional area of transverse reinforcement in beams and columns, and reducing the shear capacity of the section. In concrete slabs, this can reduce the shear strength of the slab close of the columns, and increasing the chance of punching shear failure. In footings, the corrosion can result in shear failure of the footing, anchorage failure, or flexural yielding of steel reinforcement.

2. Fatigue

Another structural effect of corrosion is on the fatigue strength of steel elements, connections, and RC elements. Corrosion may accelerate fatigue crack propagation in structural steels. Development of pitting corrosion introduces additional points of stress concentration at which cracking may develop, which will reduce the fatigue strength. Apostolopoulos (2006) studied the effect of corrosion on high and low cycle fatigue of reinforcing steel.

Weijian Yi et al (2010) studied the effect of corrosion on the fatigue behaviour of reinforced concrete beams. They concluded that “The corrosion of steel markedly affects the fatigue performance of RC beams. As the mass loss percentage of corroded steel reinforcement increases, the fatigue life of the beams decreased.”

3. Reduced Steel-Concrete Bond

The capacity of composite elements such as RC elements depends on the characteristics of concrete-rebar interface. When steel corrodes, the products of corrosion expand. This will leave a poor quality steel layer over the surface of the reinforcement. This layer has a poor bond with surrounding concrete; therefore, it will reduce the capacity of the section. In case of lap splices or anchorage, this may reduce the effective length of anchorage, and resulting in premature failure of sections. Stanish (1997) studied the effect of corrosion on the bond strength in RC elements.

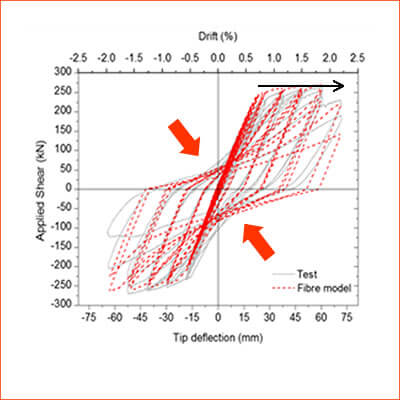

4. Limited Ductility

Corrosion can significantly reduce the ductility of RC sections. This is critical in seismic design and evaluation. Corroded sections have lower ductility, which means their plastic deformation is limited. This will affect the seismic response of the elements. Corrosion of reinforcement in the lap splices will affect the load transfer in the laps, preventing the to develop yield stress. Asri and Ou (2011) studied the seismic response of corroded bridge columns by nonlinear pushover analysis.

How to Evaluate Corrosion in Concrete?

While there is no way to prevent corrosion from happening, there are certain methods that have been developed to protect and maintain reinforced concrete elements. Using corrosion inhibitors, cathodic protection, and epoxy coatings has proven to be effective in managing the rate of corrosion. However, proper inspection and monitoring of RC elements is key in preserving their durability and structural performance over time.

1. Half-Cell Corrosion Potential Mapping

Half-Cell Corrosion Potential Mapping is an effective procedure in evaluating the likelihood of active corrosion in RC elements. The test is the most widely used procedure for the inspection of concrete bridge decks, and parking garage structures.

2. Surface Electrical Resistivity

Surface Electrical Resistivity is a cost-effective and rapid nondestructive test that can be used to evaluate the durability performance of concrete materials. The test can be used to assess the permeability (conductivity) of concrete against the ingress of aggressive agents such as chloride. Electrical resistivity test has been adapted by the AASHTO TP95, and several DOTs and MTO.

3. Ground Penetrating Radar

Ground Penetrating Radar (GPR) has proven to be an effective nondestructive test method for rapid screening of large concrete components, such as bridge decks, and parking garage slabs. The test can be to identify the locations that require further testing and inspection. While GPR cannot show corrosion directly, it can help experienced users with identifying areas with higher likelihood of corrosion.

Jonathan Hampton

Every issue would be prevented by the use of corrosion PROOF rebar

Yes. I said proof-- not resistant

You can have corrosion proof for the price of corrosion prone and at the fraction of corrosion " resistant".

FPrimeC

could you please provide more information about this corrosion-proof steel? Thanks

Mathieu champagne

GFRP rebar is commonly used in Canada as primary reinforcement. It unmatched durably and low cost compared to stainless makes it the only corrosion-proof reinforcement. Even stainless corrodes.

www.vrod.ca

alexis borderon

Using stainless steel rebar where needed only; edges and exposed zones, as well as in joints, is a solution that has proven to be efficient and currently used by leading consultants.

Poorna Ratnaweera

I guess corrosion resistant rebars and stainless steel rebars would be costly solutions. Wouldn't it be easier and more cost effective to seal concrete surface to prevent possible surface cracks and any micro size openings which would expose steel rebars to air which starts to corrosion reaction?

FPrimeC

Coatings are one effective way for the maintenance of these facilities.

Abdelrahman

Best way to eliminate all corrosion mechanisms in Concrete is to prevent concrete from absorbing water, sealants & coatings are not effective & require annual Maintinance, producing Hydrophobic & pore blocking (HPI) Concrete is the Best time proven method.

Ramachandra H V

Poorna - your suggestion is out of the box and would be the best and cheapest solution in terms of construction - time as well as cost effectiveness.

However, at the present time when construction practices, in the Indian context , wherein the cover for the reinforcement is enhanced to nullify the permeability of the corroding environment has been the effective solution as it is a question of affordability and cost effectiveness. Unless it is a project of substantial cost how often do we use an Engineer to guide let alone supervise the needs/requirements of the end user/client? Often the skilled tradesman is relied upon to resolve the issues.

As a compromise and on the question of reliability is adviseable to have the external reinforcements closest to the aggresive environment done with SS (there are doubts expressed on this) or coat the reinforcements with an anticorrosive paint like solution before placement - but this should be after the cutting and bending of the reinforcement bars (labour oriented).

The whole problem now is being overcome with the use of GFRP reinforcements - said to be cheaper substitute and obviously non-corrosive. Almost all the parameters discussed ain the blog like strength, bonding, ductility, fatigue, shear capacity etc are addressed and the deficiencies obliterated.

FPrimeC

Using stainless steel is getting more and more popular, and provides a longer durability.

Jesus Rodriguez

See Contecvet Manual on corroded concrete structures at www.ietcc.csic.es

Okan duyar

This is not a simple topic to conclude in few words. There is material, construction / constructability and service exposures to be considered for each project and member. Some segments or some exposures can only be built by stainless steel for longer service life, some others can be combination of multiple options, higher strength, exposed surface stainless steel or sealers. If nothing is manageable to maintain service of structure than corrosion protection.

FPrimeC

very good note/ Thank you

ian C

GFRP is a corrosion proof reinforcing product. All other forms of steel including Stainless Steel will eventually move to a state of least energy; hence will degrade / oxidise, increasing thier vulnerability to the same corrosion characteristics listed in this article. GFRP remains significantly cheaper in most places in the world and is well known to be significantly (50%) more carbon efficient. The surface preparation will only 'protect' while active, and while within the boundaries of crack width tolerances. Should a crack be created by traumatic events a GFRP reo will retain its corrosion proof characteristics.

Deterioration of Concrete Structures | FPrimeC Solutions

[…] Structural Effects of Corrosion […]

Abdelrahman

Its important to note that corrosion occures not only in reinforcement rebars (Chloride Attack), others forms of corrosion occures in concrete, such as Sulphate Attack to cement paste, Alkali - Silica reaction, Delayed Ettringite Formation, Freezing & Thowing...etc all of those have one common denominator, which is WATER, keep water out of Concrete and you'll have a durable & corrosion free Concrete for the service life of the structure.

This is what we have proven over 60 years of using Everdure Caltite Concrete.. www.cementaid.com www.cementaid.co.uk

4 Methods of Condition Survey for Bridge Decks | FPrimeC Solutions

[…] is the delamination of concrete, which could eventually trigger other damage mechanism, such as corrosion. The maintenance of deck slabs is quite challenging mainly because it normally involves large […]

Deterioration of Concrete Structures | FPrimeC Solutions

[…] Learn More: Structural Effects of Corrosion […]

Effect of Solar Eclipse on Concrete | FPrimeC Solutions

[…] 2. Structural Effects of Corrosion […]

Carl Tudor

We are using zinc metalizing to prevent corrosion of rebar in various types of concrete structures including areas in salt water. The zinc ions have been shown to penetrate twenty feet into the porosity of the concrete. Please contact us for additional information. Metalize.net

Jasmine Paulos

Great information.Corrosion is a dangerous and extremely costly problem.The most common kinds of corrosion result from electrochemical reactions.Some metals acquire a natural passivity, or resistance to corrosion. This occurs when the metal reacts with, or corrodes in, the oxygen in air.

Non-Destructive Testing of Concrete Tanks | FPrimeC Solutions

[…] The contents stored in the tanks, on the other hand, can lead to deterioration of concrete (i.e. corrosion of steel rebar). It is very common to find cracks on concrete surface. While most cracks may not pose great risk […]

Common Defects in Bridge Structures | FPrimeC Solutions

[…] Corrosion (read more) * Carbonation *Alkali-Silica Reaction (read more) * Influence of High Temperature * Creep and […]

Jasmine Paulos

This article is very informative and it is really nice to know about rebar too, Thank you for sharing this. Keep sharing such things and updating us.

jitendra

Amazing post,thank you for sharing this knowledgeable post, really this is very helpful.

Charlotte Clark

Truly an informative blog. It will surely help many people who are working in industries especially because they face corrosion related issues on a regular basis & these issues make them suffer a lot of time. On the other hand, technological advancements are providing a solution for industries. like there are many instruments available in the market which not only manages flow rate but they are corrosion resistant as well. So do write a blog on such instruments as well & Keep writing. People need this kind of informative stuff to read.

jitendra

Amazing post, thank you for sharing this knowledgeable post, really this is very helpful.

Sabrina Addams

It's really interesting to read about how corrosion can speed up fatigue and the development of cracks in steel structures. My family and I live in a very humid environment, so corrosion and rust are concerns. I will look into making sure our concrete and other foundational materials are waterproofed by a professional.

Rebecca Gardner

It was interesting when you talked about how corrosion causes materials to lose strength by reverting to a state of lower energy. Now that I think about it, I'd be interested to learn about how steel becomes rated as "structural" and what methods are used to protect the metal from corrosion. I enjoyed reading your article and learning more about the causes and effects of corrosion, so thanks for sharing!

Eileen Benson

I like when you explained that corrosion affects the mechanical components of metal and isn't just a durability related issue. Now that I think about it, I'd be interested to learn what kinds of plating are available to help metal become more resistant to corrosion. Your article explained corrosion in a way that was easy to understand, so thanks for taking the time to share!

Md. Nurul Hoque

Steel is already rusted as work is stopped due to corona, What measures can we take to use it?

Thomas Clarence

It was interesting when you explained that the corrosion of steel can reduce the effectiveness of components that are used in structures. As far as I know, the stainless variant of steel prevents it from aging and being affected by corrosion. It would be interesting to learn more about how stainless steel is used in structural construction.

Civil Lead

Great info, thanks for sharing i

Olivia

Such a great article on corrosion, Thanks

Skiritng

Very nice info for this type of article we can be good readers only if u put good in uaslf

Braden Bills

I want to get a building made, and I want to make sure that it's sturdy. It makes sense that using structural steel would be important! I'll make sure that it's incorporated right so that it doesn't corrode.