Nondestructive Testing have great applications in the concrete construction industry. It helps designer, construction engineers, and contractors the ability to verify the quality and integrity of built structures, identify and quantify potential defects, and record as-built condition like never before. The author has several years of combined research and industrial experience in helping construction industry in Canada, and has witnessed how NDT can help identify and quantify location and extent of potential defects in a relatively short time, and on a very good budget. This article takes a quick look at some of the most common problems in concrete construction, and how NDT methods can help.

THE PROBLEM – DO NOT DRILL

Imagine you walk into your construction site, and you see someone is setting up his core drilling machine to punch a hole into what you have been planning, working, and building for weeks or even months. You won’t like that, will you ?!

If it is Brand New, You Don’t Want Drilling to be the 1st option

Concrete is the most widely used construction material around the globe. With all the improvements in the construction practice, and the most up to date codes and guidelines, things might go wrong for one reason or another, and you want to be prepared for the worst.

Things can go wrong for many reasons:

-

- You have an extremely cold day, with a malfunctioning heating system on a Friday afternoon;

- You have an extremely warm day, and curing can not go as planned;

- Concrete pump stops working, and there is a long delay between concrete lifts;

- You are pouring into a massively reinforced foundation block, and the rain from yesterday has left a bed of silt at the base of the formwork.

and the list goes on and on.

In such events, contractors, and design engineers want to perform a proper assessment of defects, and understand if it will have negative consequences on the overall performance of the structure, whether structural or durability.

THE NDT DILEMMA

It is a common mistake that nondestructive testing is only applicable to existing structures. Far from true. In fact, NDT-based quality control and quality assurance methods is widely accepted in many parts of the world. Why is that important? Because you can hardly find an owner or an investor who would be happy to see you making a swiss cheese out of his concrete wall, or beam, or floor. Using Nondestructive Testing mean less drama in the field !

With the most recent innovations in concrete scanning using GPR, Ultrasonic Pulse, and Impact-Echo, we can significantly minimize our reliance on these cores. The application of NDT in the assessment process will save TIME, reduce intrusive work, MINIMIZE DAMAGE to a brand new facility, and causes LEAST INTERRUPTION.

1. Concrete Quality and Consistency

Nondestructive Testing can help construction managers, project coordinators, and design engineers with a better evaluation of concrete elements. During construction, certain construction problems can result in defects or anomalies, such as:

- Honeycombed Concrete

- Segregation

- Voids or Air pockets

- Voids in post-tensioning conduits

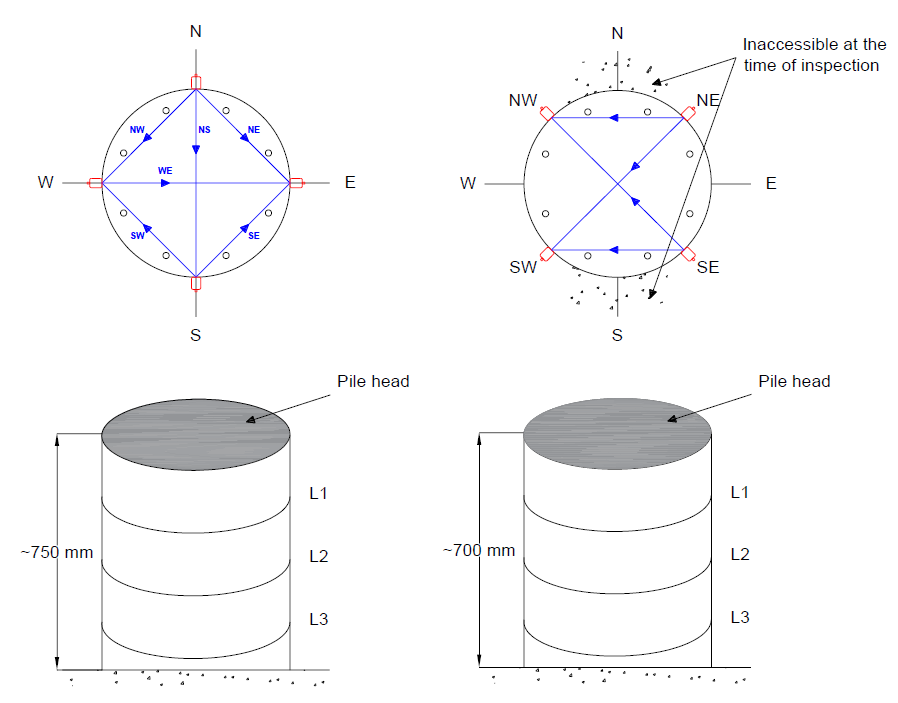

Different NDT methods can be used to assess quality and integrity of concrete elements. For example, Ultrasonic Pulse Velocity can be used to evaluate the overall quality of concrete, while ultrasonic Pulse-Echo can reveal sub-surface voids and defects; A combination of impact-echo, ground penetrating radar, and ultrasonic pulse echo can help identify air voids in the conduits.

2. Low Concrete Strength – Low Breaks

Concrete strength (compressive strength) is by far the most important property of concrete. It represents the mechanical characteristics of concrete; The 28 days compressive strength of concrete cylinders or cube samples has widely been accepted as the minimum specified concrete strength in most design codes (ACI 318-14, CSA A23.3-14). Concrete Strength is also considered a key factor in obtaining desired Durability Performance.

During construction in the cold season, we see many contractors have problems with low breaks (lower than expected compressive strength at certain age). If there is no extra concrete sample left, it would be very difficult to evaluate when concrete reaches the desired strength. It is also critical to measure the strength before loading the element. This is critical in concrete slabs, columns, and foundation elements;

A combination of Rebound Hammer and Ultrasonic Pulse Velocity can be used to accurately estimate the concrete strength. For mass concrete, or for large areas (slabs, walls, foundations), the method can help identify the locations with lower compressive strength, and help minimize the repair/remedy works.

3. Cold Joints – Quality and Integrity Issues

Cold Joints are a common observation in many concrete construction projects. While most cold joints are Ok (apart from not so nice looking scar they leave), there are some joints that need proper inspection and even repair before going for the ride.

Different NDT methods have been developed to assess quality and integrity of concrete on or around the cold joint area, namely, Impact-Echo and Ultrasonic Pulse Velocity. If there is a risk of more serious defects (such as voids), Ultrasonic Pulse Echo method can be useful.

Ultrasonic Pulse Velocity for Quality Control of Cold Joints

4. Hidden Defects

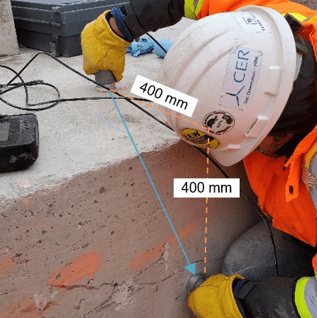

NDT methods can help you see what is hidden underneath concrete surface, so even if you are planning to take concrete cores, you can determine where would the best place to extract the sample.

NDT methods such as GPR and Ultrasonic Tomography can help contractors in selecting the locations based on accurate data from the sensors, reduce the guesswork, and avoid making holes after holes.

NDT can help identify and locate sub-surface defects in areas with limited access such as tunnels, and trunk sewers.

5. Verification and Documentation

If there are certain surface or subsurface defects during the construction, engineer of the records might require proper review and documentation of existing condition, before and after remedy works. Non-destructive tests have the advantage to minimize the amount of intrusive work. Since these tests won’t affect the existing structure, the inspection and testing process won’t stop other tasks and items on the schedule. Most NDT equipment are portable, battery operated these days, and they can be operated using one or two technicians and/or engineers in most scenarios.

Simple NDT methods such as GPR can help scan the location of rebar (i.e. when a new components is added to the original design, and needs proper anchorage to an existing slab or wall). Rebound hammer can be used to assess uniformity and strength class for a large area in a very cost-effective approach.

6. Quality Control and Quality Assurance

When things aren’t going as they should, contractors, construction engineer, project coordinators, and design team should work together towards finding a solution to carefully assess the situation, and come up with proper remedy plan. Those conversations have and will never be easy and friendly.

This is where third-party inspection companies equipped with extensive knowledge of construction defects, concrete issues, and nondestructive testing can help parties involved. NDT can help collect key information about the integrity and quality on or around the area of interest.

6.1. Extra Confidence

NDT-based quality control and quality assurance tests can bring a new dimension in understanding the following:

- Possibility of Having Defect, and their type

- Location of Potential Defects

- Extent of Potential Defects

- Estimate Severity of Defects

- Overall assessment of effects on structural integrity and quality (durability performance)

6.2. Reduce Guesswork – Reduce Areas

Since NDT is totally non-intrusive, it can easily be performed on a wide area. This provides a unique platform for assessment purposes. Test results can be used on a comparative basis and help engineering teams involved find the boundaries of the area that has issues such as extra wide cracks, extra low concrete strengths, etc.

6.3. An Opportunity to Revisit the Past

When you are building an important facility, such as a wind turbine, or a hydro dam, you would always consider evaluating the concrete structure in a certain period to make sure defects are dormant and are not affecting structural performance or durability performance. Implementing a NDT-based quality control allows for revisiting the information collected during construction, re-do the tests, and compare test results. For example, we can see if a crack that was shallow and small has in fact propagated deep into concrete or not.

CONCLUSION

Over the past few years, My colleagues and I had the opportunity serve amazing contractors across Canada. We have helped engineering teams from the windfarms of Alberta and Ontario right to the LRT projects in the Greater Toronto Area. We have worked on many residential facilities such as high rise condominiums, as well as industrial facilities, power plants (hydro, nuclear, gas), mines. This brief note aims at familiarizing contractors with the most common NDT methods in the market:

- NDT-based Assessment can reduce the inspection timeline, minimize the downtime, and results in less intrusive work

- Most modern NDT devices can deliver reliable and accurate information about defects in concrete; so next time you want to drill, give NDT a chance.

- Educated owners are asking for less intrusive testing and inspection methods. At the same time, they want to make sure their investment has adequate and satisfactory structural, mechanical, and durability performance. NDT methods can help contractors, and design engineers minimize the guesswork, and optimize the workflow.

Nabeel Nassar

it is good workshop, it worth the time

Kola Onifade

Very interesting discussion today. Thanks a lot for the information.

I will like to know more on this non destructive testing.

I am a graduate of Geophysics and interested in the application of this methods in solving human challenges in the concrete slabs or pile etc.

Inspection of building

Thanks to the author for sharing such a great post. The article was very well written and applications of non-destructive testing in concrete construction. It can be really great for people like me who are looking for grabbing more knowledge about it.If you are looking same kind of valuable information, then can also visit Csiscan.nz

Eli Richardson

I'm glad you mentioned how important it is to quality assure a construction project. Recently, one of my cousins's been interested in investing in construction projects. He asked me if I wanted to invest too, but I'm not sure about it. That's why I researched construction quality, and I believe your information will help me out. Thanks for the tips about how a structure's foundation materials are key to its quality and success.

Taylor Hicken

You made a good point when you shared that concrete is a material that is widely used in a lot of construction projects. It is important to ensure that the pumping work will not stop, otherwise, it will affect the whole project. I would like to think if a company needs to hire a concrete pumping service, it should consider working with the one that has the necessary equipment that is in good condition.

Braden Bills

I want to get a nice home made, but I'm not sure how to go about it. It makes sense that working with a professional for this would be important. They would be able to ensure that I put everything together right.

John Carston

I like how you mentioned that it is important to inspect the concrete structure to make sure defects will not affect structural performance. My uncle mentioned to me last night that he is hoping to find a reliable concrete pumping service for their upcoming construction project and asked me if I have any idea what is the best option to do. Thanks to this informative article and I'll be sure to tell him that he can consult a well-known concrete pumping service as they can answer all their inquiries.