Scope

FPrimeC Solutions was hired by Hayman Construction Inc. to perform Quality Control on Concrete Pile Head in Toronto, Canada. Minor surface defects such as honeycombing was observed over the circumference of the pile head, and the client was interested to know if the surface defects has a negative impact on the overall quality of the pile element.

NDT-Based Solution for Quality Control of Concrete Pile Head

Since the pile had a very large cross sectional dimension (>2.5 m diameter), and the area under investigation was the pile head (shallow depth), the low strain impact integrity (PIT) was not ideal. Moreover, no access tube was built in the pile element, therefore, performing the conventional Crosshole Sonic Logging (CSL) to assess the location and extent of potential defects was not practical.

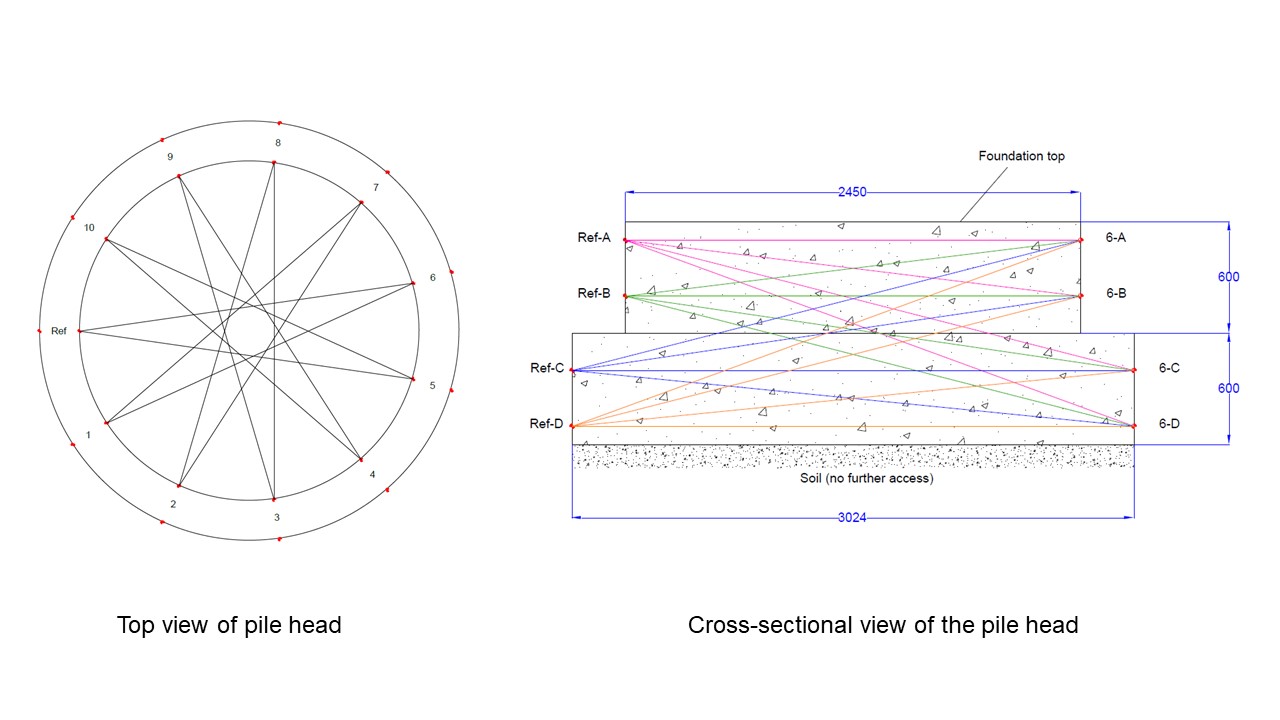

A customized test scenario was designed and used in order to assess the quality of concrete in the first 3 ft of the pile head. The Ultrasonic Pulse Velocity (UPV) was utilized by FPrimeC engineers in a diagonal pattern. The cross section of the pile was divided into 11 equal piles. The UPV was measured along each trajectory. Moreover, in the similar way to CSL tomography, diagonal trajectories along different heights were also tested.

The test allowed FPrimeC engineers collect critical information about presence of major defects within the pile head. The ultrasonic pulse velocity was compared at each trajectory, and was examined against most widely used references.