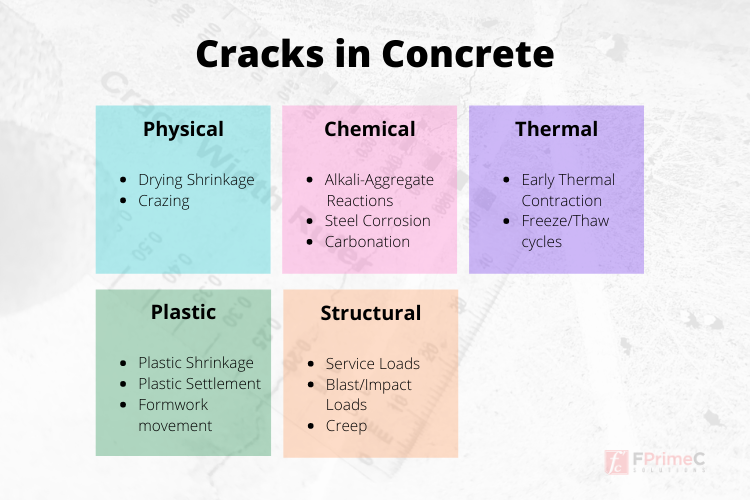

Cracking is a common observation in concrete structures. Cracks can be a result of plastic shrinkage, or constructional movements. Moreover, cracks can happen as a result of overloading concrete elements, or creep. Chemical reactions such as alkali-aggregate reactions and corrosion can induce cracking. Material and Structural engineers are interested in the main reasons behind concrete cracks, and determine the extent and severity of existing cracks. Two parameters are often used by engineers to characterize cracks: crack width, and crack depth. In this article, we will review 3 methods for evaluating crack depth in concrete.

What is Crack | Why Does Concrete Crack?

A crack is a linear fracture in concrete which extends partly or completely through the member (OSIM, 2008). In a concrete element, tensile stresses are initially carried by the concrete and reinforcement. When the tensile stresses in the beam exceeds the tensile capacity, the concrete cracks. After this point the tensile force is transferred completely to the steel reinforcement.

Cracks can occur during the concrete construction, placement and curing. They can also at any time during the service life of the structure. Cracks cab be sign of structural problems, or a result of concrete deterioration. Several issues can result in cracks in concrete, including:

- excessive external loads

- external restraint forces

- internal restraint forces

- differential movements

- settlements

In a concrete element, the crack (shrinkage, thermal, and service loads) width and distribution is mainly controlled by steel reinforcement. In fiber-reinforced concrete, fibers help control cracking. Cracks that are caused by internal or external chemical reactions, or a result of accidental loads (i.e. blast, or impact load from accidents) are different in their nature and require further investigation to assess their impact on structural integrity and durability performance of the element.

How To Evaluate Concrete Cracks ?

Visual inspection and monitoring is the first step towards understanding the nature of existing cracks, and the underlying causes. For example, inclined cracks over concrete beams near the supports can be a sign of shear stress, or cracks with a sign of rust can be a result of steel corrosion. Usually, crack widths are used to assess the severity of concrete cracks, whereas crack depth is used to evaluate overall structural integrity of the element.

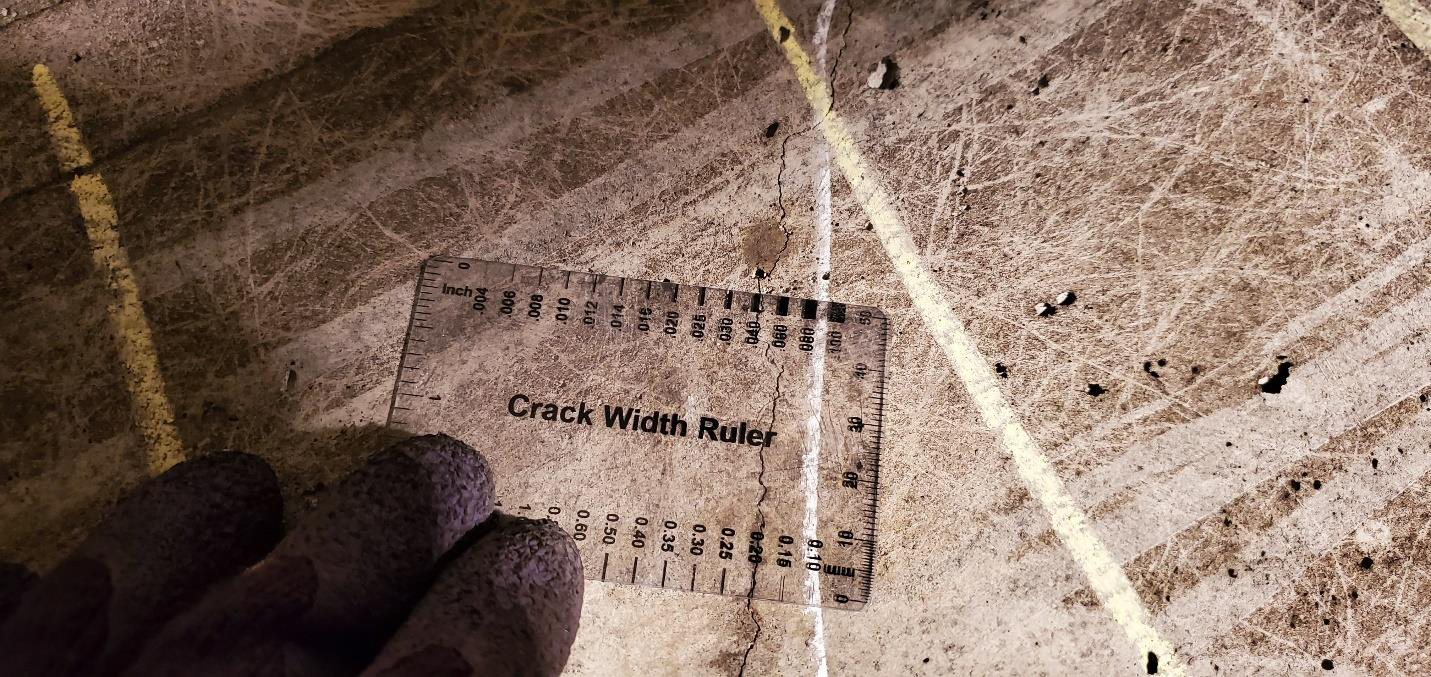

1. Crack Width

Crack severity on the surface of concrete is normally measured using a crack width ruler (crack gauge). Depending on the opening of the cracks on the surface, cracks can be described (as tiny as hairline, or severe (few millimetres opening).

2. Crack Depth

There are cases where structural engineers are interested in the crack depth measurement. Crack depth is used to evaluate structural integrity, and verify durability performance. Crack depth measurement can help repair contractor in evaluating the repair costs.

Depending on the nature of the project, engineers rely on different intrusive and non-intrusive techniques to estimate the crack depth.

Crack Depth Measurement in Concrete

I. Visual Examination of Concrete Cores

Extracting core samples from the defects is considered a popular method among inspectors and engineers. Depending on the nature of the crack, and the location of crack (is it located in critically damaged area?, is located on or around post-tensioning cables), core samples can provide information about the extent, depth, and severity of cracks. One approach is simply extracting cores, and visually examining the corehole and the core for possible causes of the crack. In another method, dye is injected (using pressure) into surface cracks. Later, concrete cores will be taken from the area under investigation. The sample is studied under microscope for determining the depth of cracks in concrete.

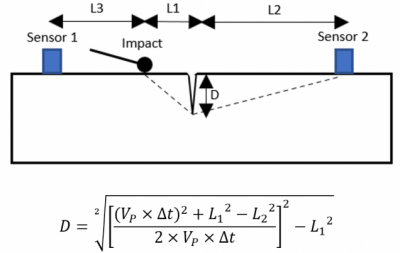

II. Impact-Echo Method

In Impact-Echo test, a stress pulse is generated at the surface of the element. The pulse spreads into the test object and is reflected by cracks, flaws or interfaces, and boundaries. The surface response caused by the arrival of reflected waves, is monitored using a high precision receiving transducer (Malhotra and Carino, 2004). When stress waves travel within the concrete element, a part of emitted acoustic waves by the stress pulse on the surface is reflected over the boundary layers, where different the material stiffness changes. The data received by the transducer is normally analyzed in the frequency domain to measure the wave speed and the thickness. This procedure has been standardized as the ASTM C1383, “Standard Test Method for Measuring the P-Wave Speed and the Thickness of Concrete Plates Using the Impact-Echo Method”.

Impact-Echo can be used to assess the depth of surface cracks. To do so, an impact-echo test setup with two transducers is needed.

where L1 is the distance between the horizontal impact point and the crack; L2 denotes the distance between the second sensor and the surface-opening crack; L3 represents the distance between the impact point and the first sensor; VP is the P-wave velocity; and Δt denotes the travel time for the P-wave from the start of the impact to its arrival to the transducer 2.

How To Test Concrete Using Impact-Echo ?

III. Ultrasonic Pulse Velocity (UPV)

Ultrasonic Pulse Velocity (UPV) is an effective non-destructive testing (NDT) method for quality control of concrete materials, and detecting damages in structural components. The UPV methods have traditionally been used for the quality control of materials, mostly homogeneous materials such as metals and welded connections. With the recent advancement in transducer technology, the test has been widely accepted in testing concrete materials. Ultrasonic testing of concrete is an effective way for quality assessment and uniformity, and crack depth estimation. The test procedure has been standardized as “Standard Test Method for Pulse Velocity through Concrete” (ASTM C 597, 2016).

To learn more about UPV method, and its applications, click here. UPV method can be used for estimating the depth of surface cracks. To do so, each transducers should be place on one side of the crack, for a given distance. Then, the distance between transducers is changed in the same trajectory. The UPV measurement will be repeated for different spacing of transducers.

Ultrasonic Testing of Concrete | FPrimeC Solutions

[…] more) 3- Establishing Homogenity and Uniformity of Concrete 4- Measurement of Surface Crack Depth (read more) 5- Prediction of Compressive Strength of Concrete (read […]

4 Methods of Condition Survey for Bridge Decks | FPrimeC Solutions

[…] more), evaluate Homogeneity and Uniformity of Concrete, Measurement of Surface Crack Depth (read more), and prediction of Compressive Strength of Concrete (read […]

BURGHAMMIARSO

Post results what is the effective way to restore it rather to demolish the whole structure.

Bob

I didn't know that the echo test could measure waves. My concrete is cracked. I'll have someone assess the depth.

Jenny Janson

Van i use eco rubber to fill cracks at home and / or use it as a damp sealer before painting the walls of my house?

Rock breaking Christchurch

From this article you will get to know about the 13 signs it's time for furnace repair or replacement. Before give a try here to get the best available content here and the article is much informative regarding work as well. I love this article, thanks for producing such great contents. I love your posts always. You must also check out Smcnz.nz it has some great insights too.

Earthmovers Bay Of Islands

Oh My God!!! This is a great blog, I am happy that I have come across this one. It’s an amazing blog to read, so many things about 3 methods crack depth measurement in concrete. Thanks for this wonderful content.

Registered Surveyor

Your article is quite helpful! I have so many questions, and you have answered many. Thank you! Such a nice and superb article, we have been looking for this information regarding the 3 methods of crack depth measurements in concrete. I enjoyed reading this article!

Afrin Khan

Such an amazing article of this. Thanks for sharing the informative article. We are a stamped concrete construction company that specializes in commercial, residential, industrial, flatwork, curb, and gutter.

Barry E. Holland

Thanks for writing this great article for us. I have gained good stuff from this website. Looking forward to your next article. I am happy to share this post to my friends. Keep it up.

Vashpanov

See:

Yuriy Vashpanov, Jung-Young Son, Gwanghee Heo, Tatyana Podousova, and Yong Suk Kim Determination of Geometric Parameters of Cracks in Concrete by Image Processing Advances in Civil Engineering, Vol. 2019, Article ID 2398124, 14 pages. https://doi.org/10.1155/2019/2398124.

Mia Evans

Thanks for pointing out that the severity of cracks can tell the depth of the issue regarding the structural integrity of the foundation. With that in mind, I would look for professionals to check the crack on the flooring of our home. It might be a danger if it is not fixed immediately, so I hope we can get the foundation of the house repaired as soon as possible.

Hailey Miller

It really helped when you said that inclined cracks over concrete beams can be a sign of shear stress or a result of steel corrosion. Our two-story house near the beach has concrete cracks and we don't know what to do. I guess we should look for petrographic services on Monday that can provide accurate concrete analysis to ensure the safety of our family.

Taylor Hicken

I appreciated it when you shared that it is great to determine crack depth in order to evaluate structural integrity and verify the durability performance of a structure. In this way, the responsible party can determine what can be done to fix the issue. I would like to think if a company needs to fix a crack in a building, it should consider getting a product that can help fill it.

PCTE

great blog! keep it up. The flow of writing is really easy to understand.

Non-destructive Evaluation of Concrete in Mine Facilities - FPrimeC Solutions Inc.

[…] performed in various configurations enabling engineers to collect information on the integrity and crack depth of different […]