Appropriate operation and maintenance of concrete dam structures are essential to ensure the safety of the structure, and reducing risk. Concrete surfaces should be examined in a regular basis to identify spalling and deterioration due to weathering, or extreme stresses, or other physical, or chemical damage mechanism. Nondestructive Evaluation of Concrete Dams can provide useful information about the condition and quality of concrete materials, extent of damages, and mechanical properties of concrete.

What Can Cause a Dam to Fail?

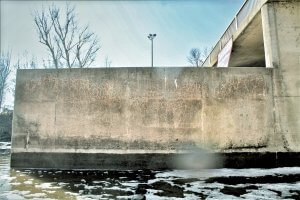

Concrete dams can develop problems or fail for a number of reasons, such as deficiencies in the design, poor construction practices/materials. Poor foundation capacity and inadequate spillway capacity are also among the reasons that can cause failure (British Columbia Dam Safety Guideline, 2016). Dams experience problems during their service life, and improper operation and maintenance result in major issues. In addition, dams can be deteriorated due to weathering, Alkali-Silica Reactions (ASR), freezing and thawing, or other chemical attack. Cracking and broken out concrete can also be a sign of structural problems (stability issues, settlement, etc). The reinforced concrete components can experience Corrosion, and reduced capacity. Erosion is a common cause for concrete deterioration in spillway floor slabs and upstream slope protection slabs.

Nondestructive Evaluation of Concrete Dams

Dam structures vary in size and shape. The inspection and monitoring of small dams can be an easy and straight forward task; however, the inspection and monitoring of larger concrete dams is a challenging task. Even basic visual inspection of large concrete dams is labor-intensive and time-consuming. It requires skilled inspectors and hard work to identify surface deficiencies in these structures. Visual inspection can is first in line, as it can identify the locations where further inspection is required. Later, we will discuss acoustic methods that can be used to evaluate the condition of concrete materials.

1- Visual Inspection by Drones

Recent advancement in drone technology, have opened a new chapter in the visual inspection of concrete Dams. Drones are used for visual inspection of concrete surface and identifying surface cracks and defects. Drones equipped with Infrared Thermography sensor can also be used for detecting traces of moisture or sub-surface deficiencies for an enhances inspection. The main disadvantage of visual inspection (with or without drones) is that the method does not provide information about the properties of concrete, or condition of concrete (physical of chemical damages).

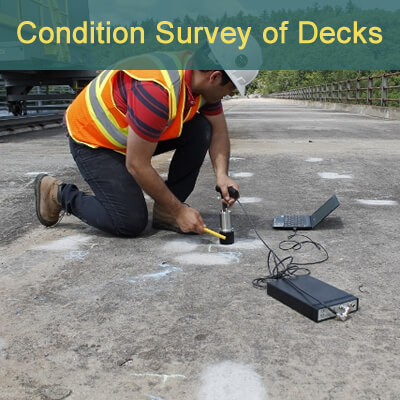

2- Impact-Echo (IE)

Impact-Echo can be used to investigate the condition of concrete and extent of cracking in concrete dams (Olson, L. D. and Sack, D. A. 1995). In Impact-Echo test, a stress pulse is generated at the surface of the element. The pulse spreads into the test object and is reflected by cracks, flaws or interfaces, and boundaries. The surface response caused by the arrival of reflected waves, is monitored using a high precision receiving transducer (Malhotra and Carino, 2004). When stress waves travel within the concrete element, a part of emitted acoustic waves by the stress pulse on the surface is reflected over the boundary layers, where different the material stiffness changes. The data received by the transducer is normally analyzed in the frequency domain to measure the wave speed and the thickness. Impact-Echo has the advantage of requiring access to only one side of the component. The method can be used to identify freeze and thaw defects in concrete spillways.

3- Spectral Analysis of Surface Waves (SASW)

The Spectral Analysis of Surface Waves (SASW) method has many applications in material characterization of multilayer systems. This can be used for in-situ evaluation of concrete quality, thickness of layer and boundary condition in multilayer systems as well as estimating the modulus elasticity. The SASW is a seismic exploration, which relies on the determining the stiffness of medium. SASW is a powerful method when only a single side access is available. Olson and Sack (1995) argues that “The SASW method is capable of providing the shear wave velocity versus depth profile of a structure, including measurements of the velocity of soils or rock behind the structure, with no coring or other damage to the structure required.” The SASW method can also be used to identify freeze and thaw defects in concrete spillways.

4- UPV Tomography / Seismic Tomography

When there is no access problems (2 or more directions available), Ultrasonic Pulse Velocity (UPV) methods can be used for evaluation of concrete properties. Ultrasonic Pulse Velocity (UPV) is an effective non-destructive testing (NDT) method for quality control of concrete materials, and detecting damages in structural components. Ultrasonic testing of concrete is an effective way for quality assessment and uniformity, and crack depth estimation. The test procedure has been standardized as “Standard Test Method for Pulse Velocity through Concrete” (ASTM C 597, 2016). The most practical form of the UPV measurement in concrete structures is the seismic tomography. This is one of the imaging techniques, which can prepare a two or three dimensional mapping from the present state of concrete structures, quantifying the internal anomalies and deficiencies based on the order of velocities. Rivard et al. (2010) shows the seismic tomography testing contour map for a cross-section of a hydraulic concrete structure.

Conclusion

Nondestructive methods such as Impact-Echo and SASW have a great potential in identifying deficiencies in concrete dams. The methods can be used to evaluate damages due to ASR, and freezing and thawing which are common in older dam structures. When access is possible, UPV tomography can be used to evaluate sub-surface deficiencies such as voids, and cracks.

beyazli Group

Hello,

we are the manufacturer of concrete block machine which produces concrete block and paving bricks. I have read your article the information you have provided is very useful.

FPrimeC

Thank you very much for your comment.

Job Changwony

How do the Alkali Silica Reaction affect dams and in which conditions?

Rodolfo Morales

wich method do you recomend to monitor a new 0 meter gravity concrete dam?