A multi-technology approach using different Nondestructive Testing (NDT) technologies is becoming the new standard in structural condition assessment. Ground Penetrating Radar has proved to be an effective method in collective key information about the structural details, however, this interesting technology comes with inherent limitations. It is important to develop a good understanding of the capabilities of GPR, and cover its shortcomings with complimentary methods such as the Ultrasonic Pulse based methods. In this article, we will briefly review the capabilities of Ground Penetrating Radar – GPR in Structural Assessment.

Key Questions in Structural Assessment

Structural Assessment usually refers to the process of collecting observations and data about the existing condition of the structure through systematic and scientific methods. This includes collecting information about:

- The Visual Condition of Structural and Nonstructural components,

- Detect Potential Subsurface Defects

- Identify Structural Details

- Determine Materials Characteristics

- Evaluate Materials Durability Properties

In order to see how GPR can help engineers in a condition assessment of structural concrete, one needs to know How GPR Works in the first place.

A general concrete scanner with frequency of 1000 MHz

A low-frequency GPR scanner (500 MHz) for a deep scan

How Does GPR Work?

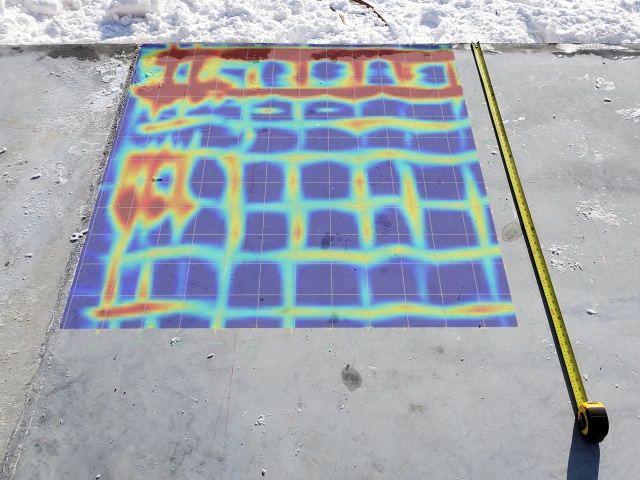

A typical modern Ground Penetrating Radar instrument consists of a transmitter antenna and a receiver antenna, connected (through wires or wireless) to a signal processing unit. GPR emits electromagnetic pulses (radar pulses) with specific central frequency to scan the subsurface medium. The reflected waves from subsurface targets (rebar, conduits, defects) are captured by the receiver antenna. Depending on impulse frequency, GPR is able to detect targets at different depths. GPR scans are either performed in a linear scan array, or area scan. Area scan combines multiple line scans (collected in two perpendicular direction) to provide slice maps of subsurface.

In general, when there is a need for high resolution scanning, antenna with high frequency is required; however, the depth of penetration will be low. Lower frequencies are required when the targets are located in deeper levels.

Capabilities of GPR in Structural Assessment

The SHRP2 report provides an interesting overview of the using GPR in structural assessment. In general, GPR can be used for evaluation of the thickness of concrete deck or concrete lining, estimating the concrete cover thickness, identify rebar configuration, and characterization of

delamination potential. The following will focus on 3 main applications of GPR in structural assessment.

1- Locate Rebar – Rebar Scan

GPR is widely used to determine the Location and Distribution of steel reinforcement in concrete. A high frequency antenna can help inspectors map out reinforcement right on site. Maps can be calibrated to accurately estimate the depth of steel bars.

- Location of steel bars

- Number of steel bars over length

- Determine approximate depth of steel rebar

- Identify thickness of concrete elements (shallow thickness elements)

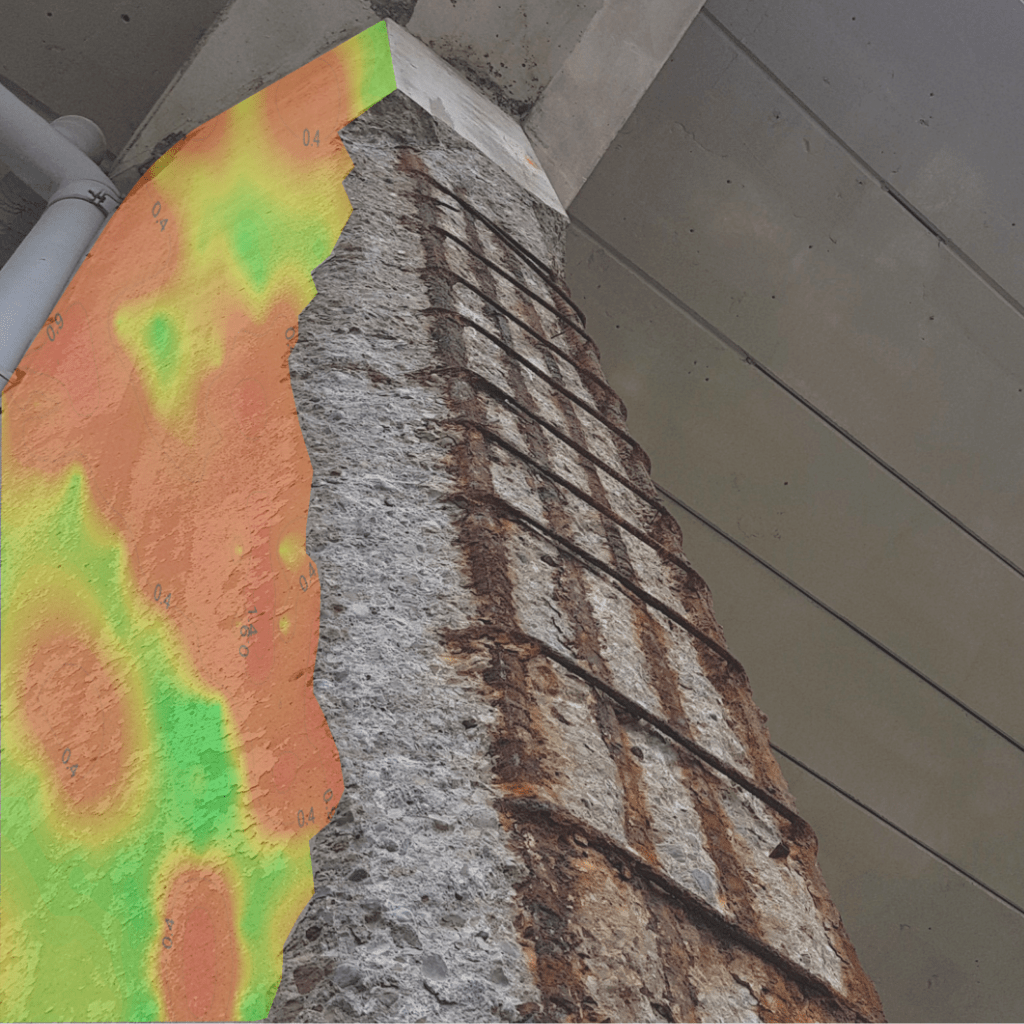

2- Detect Voids or Delamination

In theory, GPR would be capable of detecting major voids: that is if the voids are large enough compared to the cross-sectional dimensions of the element.

When it comes to detecting delamination, the use of GPR should be handled with care.

3- Detect Subsurface Anomalies

GPR can be used as rapid screening of large concrete surfaces, such as parking garage slabs, or concrete bridge decks.

GPR antennas can be mounted on vehicles enabling deck scan at a much higher speed. The method can be used to estimate the total area that might require further investigation. For each particular application, it is important to select the suitable frequency.

GPR in Structural Assessment

Practical Limitation of GPR in Structural Assessment

1- Mechanical Properties of Concrete

GPR uses electromagnetic waves to scan subsurface of concrete elements. The method does not provide any information on the mechanical characteristics of concrete, such as stiffness, or strength.

In order to complement GPR results, it is strongly recommended to use Rebound Hammer and/or Ultrasonic Pulse Echo scans to evaluate concrete quality, uniformity, and strength properties.

2- Corrosion of Steel Bars

There is no direct way to determine corrosion condition of steel rebar using GPR. However, engineers and NDT professionals may be able to customize certain practices to collect information about the corrosion condition through in-direct methods, such as studying the presence of major delamination and accumulation of moisture.

GPR surveys are sensitive to corrosive environments, and results can be evaluated by experienced NDT specialist to determine the area with potential corrosion (Note: on a comparative basis, fine tuned by direct comparison to other NDT methods or minor intrusive tests for validation). It is strongly recommended to complement GPR scans with Half-Cell Corrosion Potential Maps in order to study the corrosion condition of steel bars.

pcte

Thanks for the amazing post. I am sure many people will get a lot of insight after reading this. GPR systems are indeed worth looking into. Keep up the excellent work of keeping people aware of these advancements.

Braden Bills

I want to have a basement made, but I want to make sure that the area around my home can support this. It's good to know that you can use a ground penetrating radar to determine how sturdy something is! That seems like a great way to determine the strength of my land.

Curtis Butler

Thanks for explaining how GPR can help you determine the location of steel bars that are present in your concrete and that maps can be used to identify the depth of the bars. My uncle and I have been thinking about having an office building constructed on the commercial property he bought last summer, but he needs to make sure that it will be safe for us to build on top of the concrete without worrying about it deteriorating over time. Maybe we should find an expert that can help us make sure that the concrete surface is properly reinforced.

Hailey Miller

It really helped when you said that GPR emits radar pulses to scan the subsurface medium. As you said, it can determine the location and distribution of steel reinforcement in concrete. I would imagine that anyone who wants to find both metallic and non-metallic targets will get a GPR underground utility locator to minimize the risk of causing property damage.

Anwer Siddiq Memon

Very informative, and very well in depth explained, the work methodology of above mentioned conditions may also be shared. Plz also share how to aquire the helpful instruments.

Chance Cook

I like how GPR can find rebar. I always wondered how I could find those. So I'll use GPR to find the rebar in my house.

Victoria Addington

It is amazing to know that GPR can be used as rapid screening of large concrete surfaces, particularly parking garage slabs, or concrete bridge decks as GPR antennas can be attached on vehicles allowing deck scan at a much higher speed. This can be very useful equipment for my friend since he's constructing a new property. I must inform him about GPR concrete scanning, so he can hire a contractor in our area that provides the service.

Sagar jadav

Thanks for information please post further of possible about how combinedly we can use the GPR and tomography to uptimize the respective scans.

Non-destructive Evaluation of Concrete in Mine Facilities - FPrimeC Solutions Inc.

[…] Ground Penetrating Radar (GPR) can help map steel rebar in concrete structures. The following can be assessed using GPR: […]