The Crosshole Sonic Logging (CSL) or Ultrasonic Crosshole Test is a widely used non-destructive test for assessing Pile Integrity and quality control of drilled shafts (piles). CSL test is a variation of Ultrasonic Pulse Velocity. In theory, the pulse velocity in concrete is a function of the modulus of elasticity, density, and Poisson’s ratio. The uniformity of concrete shaft can be assessed by measuring the pulse velocity. In crosshole sonic logging, a number of access tubes are installed inside the reinforcement cage prior to placing concrete. For the purpose of testing, the tubes are filled with water to provide acoustic coupling to the ultrasonic transducers.

The very basic format of the test involves at least two parallel tubes installed. Two transducers (a transmitter and a receiver) are lowered down to the bottom of the shaft, and are pulled up. The transit time of an ultrasonic pulse through the concrete between the tubes is measured by a data logger. As UPV transducers are pulled up, the UPV is measured and recorded versus the elevation. This provides engineers with a vertical profile of signal transit time. A modern CSL system uses an automated depth encoder to precisely record the position of the probes inside the access tubes.

Capabilities of Ultrasonic Crosshole Test

Crosshole Sonic Test is a great test for identifying Anomalies in concrete shafts such as soil inclusion, poor quality concrete (low density, low modulus), and major voids. In general, the transit time of ultrasonic pulse between every two access tubes is measured using a high precision data acquisition system. The resolution of the scan along elevation can be controlled by the rate of the withdrawal of the transducers in the tube (normally performed form the bottom to top). The resolution of the scan at each elevation depends on a number of parameters, such as the selected frequency (pulse wavelength), the number and horizontal spacing of access tubes. A modern CSL is equipped with transducers that can operate between 25 to 50 kHz, allowing detection of defects as small as 2.5” to 4” (in each horizon). It is recommended to keep the spacing of the probes to about 12’ (3.6 m).

Analysis of CSL Results

Two main method are often used by geotechnical engineers around the globe: 1) The Waterfall method, and 2) First Arrival Time (FAT). In addition, 2D/2D tomography maps can be generated to illustrate the location and extent of damage at each elevation.

Waterfall Method for Analysis of CSL Test Results

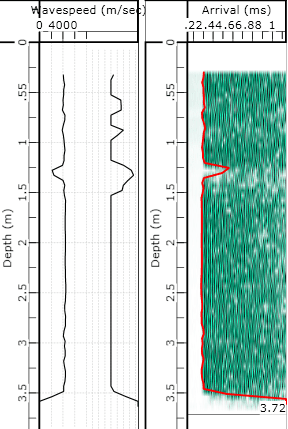

In the Waterfall method, the results are presented as a profile based on complete ultrasonic pulse time histories. As a general practice, the positive peaks are presented by a dash line, whose width matches that of the original peak, and each negative peak is illustrated as a gap, creating a dashed line. These measurements are presented as a series of dash-lines along the shaft elevation, which allows for a more detailed review of the wave train, even when the first arrival cannot be detected. Figure … shows an example of the waterfall method.

First Arrival Time for Analysis of CSL Test Results

In this procedure, the arrival time of the first peak in the ultrasonic pulse wave train is (First Arrival Time, FAT), and the overall amplitude of the early part of pulse is measured. A practical challenge in the FAT method is distinguishing between peaks in the wave train, and the noise in the construction site. This is often performed through filtering out the noise by assigning a threshold value.

Crosshole Tomography

Crosshole Tomography or tomographic analysis is an alteration of the Crosshole sonic logging that will provide image of an anomaly within the shaft. Such image shows the shape and position of the affected zone. If regular CSL (horizontal setup) shows there might be a defect in the shaft, additional tests can be performed with transducers offset vertically to provide angled pulse paths. This will enable geotechnical engineers in locating the area and size of the defect.

It is important to note that the Crosshole Tomography comes with all limitations related to effectively measuring the travel path of the pulse (which will not be straight line in most cases). The positioning of the access tubes might change along the pile length. If the CSL test results does not show any anomalies in the shaft, performing tomography test does not provide any extra information.

Key Advantages of Crosshole Sonic Logging

The interpretation of the test results in CSL test is relatively easy (compared to other tests, such as the low strain pile integrity test).

In theory, there is no limitations with regards to shaft length or diameter. The test results are not affected by skin friction, variation in soil stiffness, or damping characteristics.

The test can be further enhanced by implementing a diagonal positioning of the probes (in which the elevation of transmitting transducer has an offset with the receiving transducer). This would enable engineers in creating 2D and 3D maps of defects inside shaft.

Disadvantages and Practical Limitations

The main disadvantage of the test relates to the fact that most access tubes are installed inside the steel reinforcement cage. This would limit the amount of information that can be obtained from concrete area that lies beyond the the steel cage (which happens to be the most problematic area in most cases).

CSL test does not provide information about small horizontal defects.

Another practical consideration is the installation of tubes. As the shaft dimeter increases, the minimum number of access tubes is also increased. This will increase the number of paths that need CSL measurement (labor intensive and time consuming).

Practical Considerations

Access Tubes | Steel Access Tubes or PVC Access Tubes?

Proper selection of access tubes is critical in performing CSL test. Access tubes can either be steel, or PVC. However, experiences from North America have shown that the PVC tubes are less reliable, and might result in unwanted challenges such as debonding from the concrete. Plastic tends to lose its bond to concrete after a few weeks (following concrete placement). Since ultrasonic wave cannot pass through air, the debonding issue makes rendering the CSL test ineffective.

What is the proper size of Access Tubes?

Access tubes are typical 1 to 3 inches in diameter (40 mm – 50 mm). Access tubes are filled with water to provide acoustic coupling, as a result, they should be water tight at the ends to prevent the penetration of soil, groundwater and debris inside the tube.